Menu

- Solutions

- Videos

- Industries

- Software

- Support

- Careers

- Company

- Contact

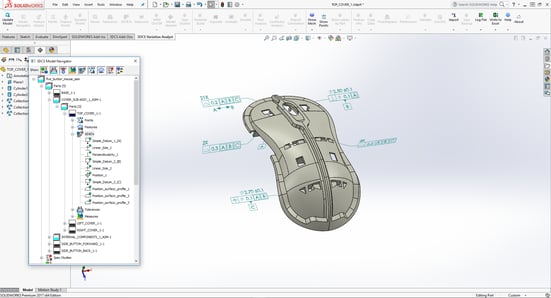

Optimize tolerances, GD&T, assembly sequence, and assembly processes through design iterations and analysis. Make changes to your model, see the results, and then push your final decisions back to your CAD model.

Using this feedback loop provides a Closed Loop Process of continuous quality improvement to reduce your product's risk of failure that leads to scrap and rework.

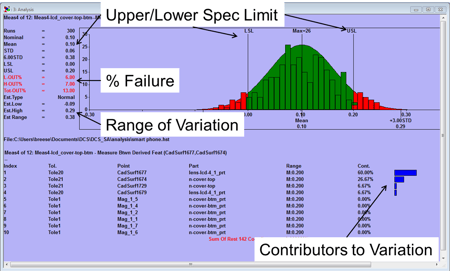

3DCS Variation Analyst utilizes Monte Carlo analysis and equation-based methods to provide a statistical report of your anticipated results. This includes your risks of failure, quality metrics (Cp, Ppk, etc), and anticipated final measurement values.

3DCS Variation Analyst utilizes Monte Carlo analysis and equation-based methods to provide a statistical report of your anticipated results. This includes your risks of failure, quality metrics (Cp, Ppk, etc), and anticipated final measurement values.

Designers and Engineers can utilize these values and the Contributor analysis to see what influences are affecting tolerance (Gap, Flush) features. After identifying the source of variation, engineers can modify the design by either altering tolerances, design, or making adjustments to the assembly process in order to reduce the contributor variation. This iterative process gives engineers the power to determine the best direction for design changes and makes it easy to find the true sources of variation in an assembly.

3DCS Variation Analyst provides true insight into your design. Use 3DCS to find key critical characteristics and hone in on areas that cause the greatest amount of variation across your assembly. At the same time, find areas non-critical to the build and loosen tolerances to allow for less expensive manufacturing processes to save time and costs.

3DCS Variation Analyst provides true insight into your design. Use 3DCS to find key critical characteristics and hone in on areas that cause the greatest amount of variation across your assembly. At the same time, find areas non-critical to the build and loosen tolerances to allow for less expensive manufacturing processes to save time and costs.

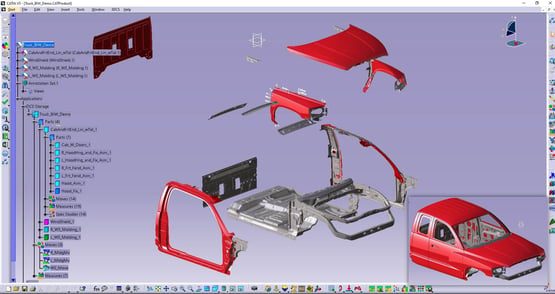

3DCS Variation Analyst calculates the variation from more than just part tolerances and tolerance stack-ups. 3DCS also considers the assembly process. This often adds additional unexpected variation to products and can cause problems during assembly.

3DCS Variation Analyst calculates the variation from more than just part tolerances and tolerance stack-ups. 3DCS also considers the assembly process. This often adds additional unexpected variation to products and can cause problems during assembly.

By simulating the assembly process, 3DCS provides insight into additional variation and possible problems that may occur.

Engineers can then use 3DCS to determine the cause of variation in the assembly process and alter it to see how it will affect their final product.

Tighter tolerances often require more expensive processes. 3DCS provides an understanding of which tolerances are critical to quality, and in the same light, which tolerances are not critical. By increasing the size (loosening) of non-critical tolerances, engineers can change the manufacturing process to less expensive options, and reduce the overall cost of the product.