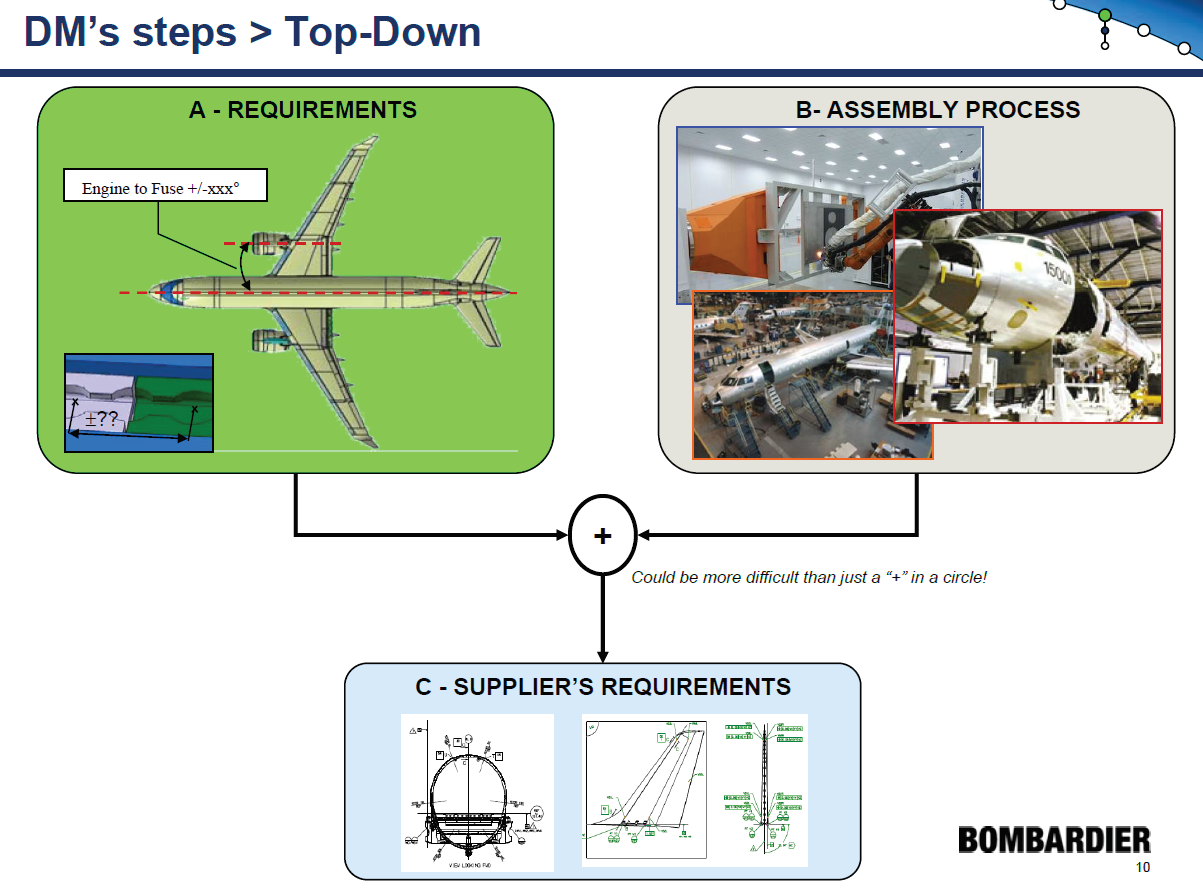

As in most dimensional management groups, the group at BOMBARDIER essentially hold to the same objectives. They achieve these objectives through an established dimensional management process:'

Once the results are passed tot he supply chain, the analysis is updated with Bottom-Up Feedback, incorporating detail part capabilities, tooling capabilities,

and internal assembly processes. Once these models have been developed, they provide a stack analysis to determine the risk of failure in meeting BOMBARDIER Aerospace requirements.

Aerospace models pose a number of unique challenges. First and foremost, the models are exceptionally large. With five or more levels of sub-assemblies, and thousands of small parts, it can be a challenge just addressing where to begin. During the development phase, changes occur constantly in design. This makes modeling difficult, as design changes are constantly coming in, requiring the model to be updated.

Finally, getting statistical data from suppliers is often next to impossible. These challenges together create an often difficult environment for modeling, and therefore require a considered response, as shown below.

DCS will never share your information with a third party or add you to a mailing list without permission. Read our privacy policy to learn more about how DCS protects your information.