DCS provides a variety of services to support your quality initiatives

Course Description

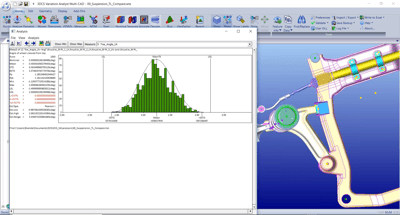

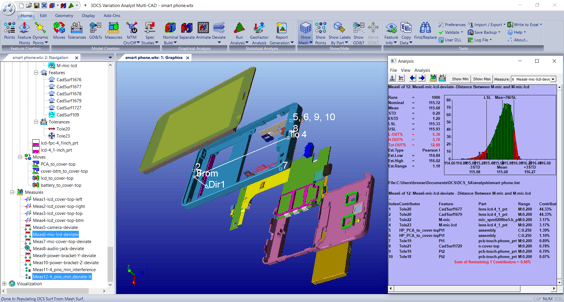

Tolerance stack analysis studies the mutual relationship between the allowed deviation limits between parts and assemblies. Stack computation improves understanding of the design solution, allows early identification of problems starting while still in the design stage, forms the basis for decision making and is used to optimize tolerances to reduce costs and enhance product performance.

This course provides the theoretical knowledge and practical know-how to perform stack computation and includes heavy practical exercises of generic problems, exercises, and full solutions of real problems (the possibility of applying exercises to parts and assemblies of your company is contingent on previous submission of drawings and assemblies). This is an advanced GD&T course.

Course Content

Let DCS support your team with on-site and remote training, model reviews, and modeling services to get your team ahead.

Our courses will fully prepare your employees to meet the challenges of Dimensional Engineering. Each offers real-world examples to make the material interesting, informative, and applicable to your own software environment.

We offer clients the opportunity to strengthen their skills and extend their knowledge in several fields. As a client of 3DCS, you’ll hear from experts in Engineering Statistics, ASME Certified Geometric Dimensioning and Tolerancing (GD&T), and 3DCS software solutions—the same training that makes our employees the best in the industry.

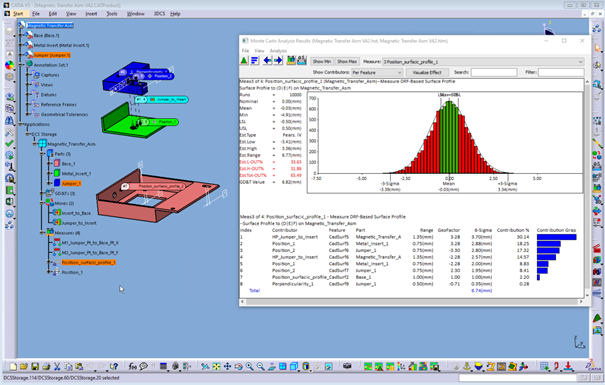

Quality is important. Getting real results and improvement from your quality processes is not easy, though. Collecting data and measurements is only the first step, as making actionable decisions from that data can take many hours of diving through large datasets, looking at huge spreadsheets and crunching statistics.

There are a number of reasons to adopt GD&T at your company:

Clarity and consistency in the design process. GD&T provides a clear and concise method for defining a reference coordinate system on a component or assembly that can be used throughout manufacturing and inspection. This reduces misinterpretations and the need for costly engineering changes and rework that can result from a lack of clarity.

Dramatic time savings. By using GD&T, engineers dramatically reduce their need for drawing notes to describe complex geometry requirements on components and assemblies.

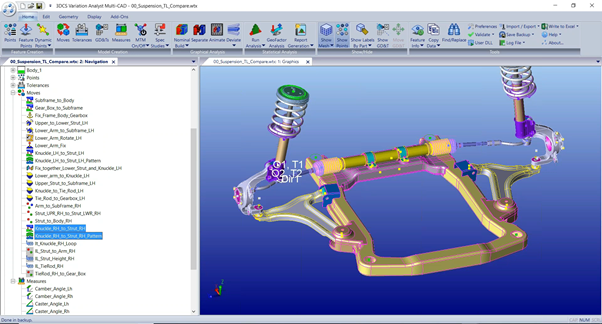

Fit with accepted design-for-manufacturing methods. The proper application of GD&T closely dovetails accepted and logical mechanical design processes and design-for-manufacturing considerations. For example, the allowable variations as defined through GD&T can be directly read, or “imported,” into 3-D tolerance analysis software such as 3DCS.

DCS offers starter and advanced courses in GD&T to get your team up-to-speed and applying GD&T concepts.