DCS develops and distributes 3DCS Software for Tolerance Analysis and QDM for SPC Quality Data Management that together provides a connected Quality Intelligence Solution.

Click the Images Below to Learn More About DCS Software Solutions

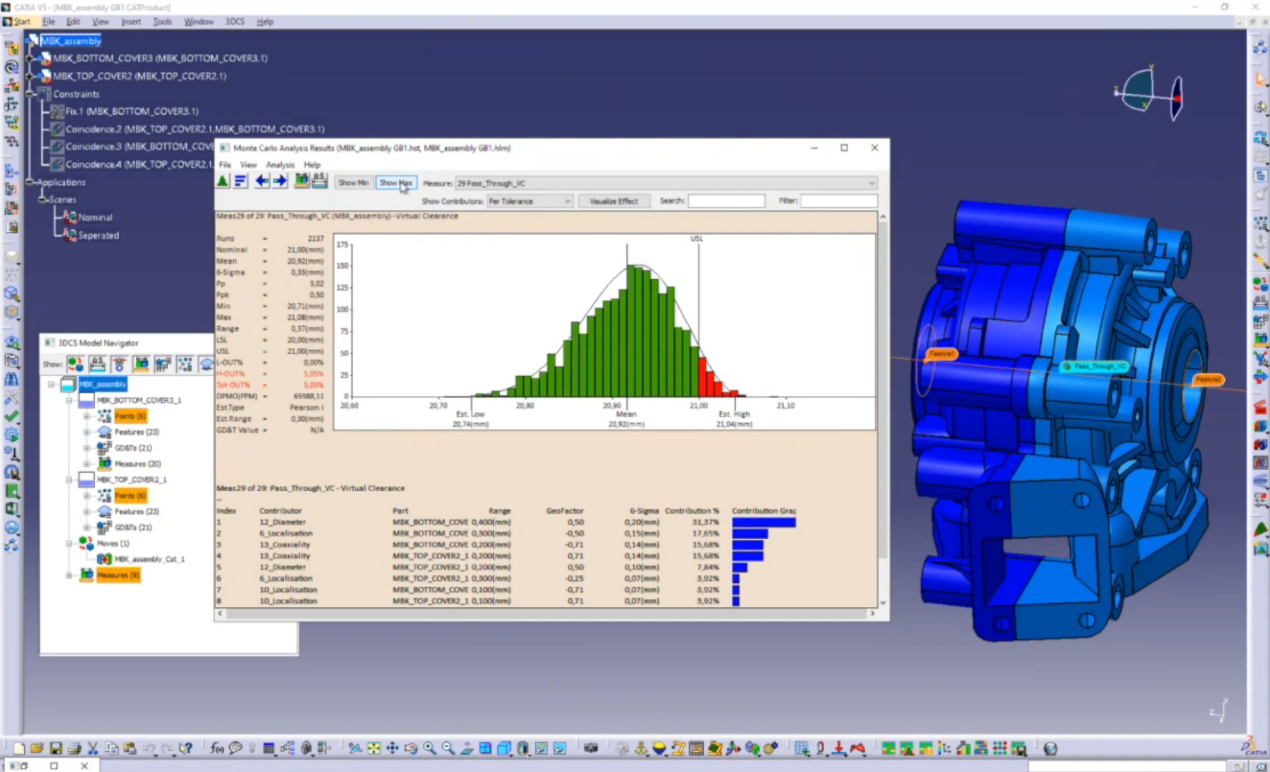

Powerful tolerance analysis software that simulated the build including both part and process tolerances. Optimize your design early and then utilize your models to root cause manufacturing issues in production.

Learn More →

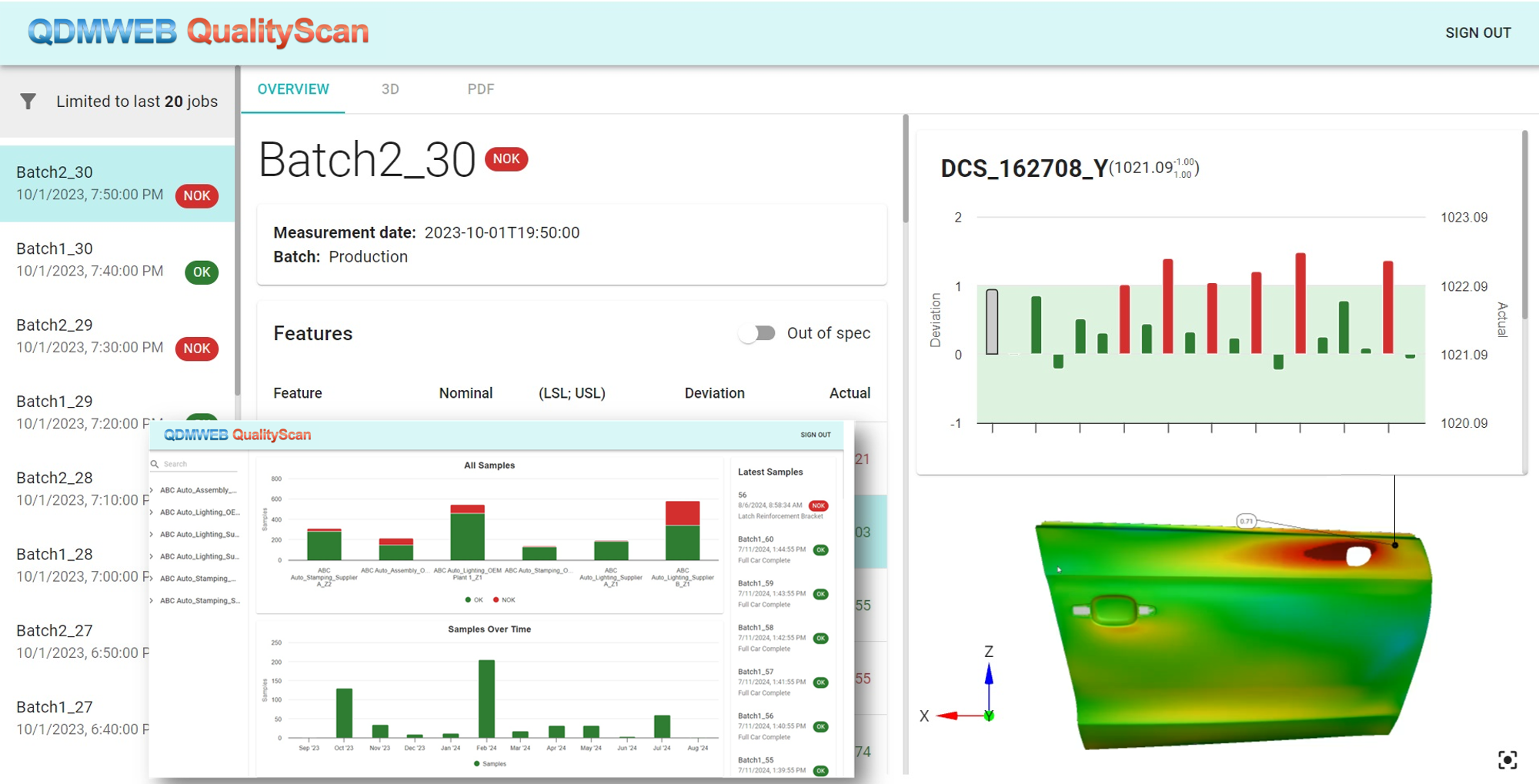

QDMWEB QI manufacturing quality management system gives you access to your quality information from anywhere, at any time, instantly. Automate your quality collection and start reducing your costs with real-time monitoring and powerful SPC tools

Learn More →

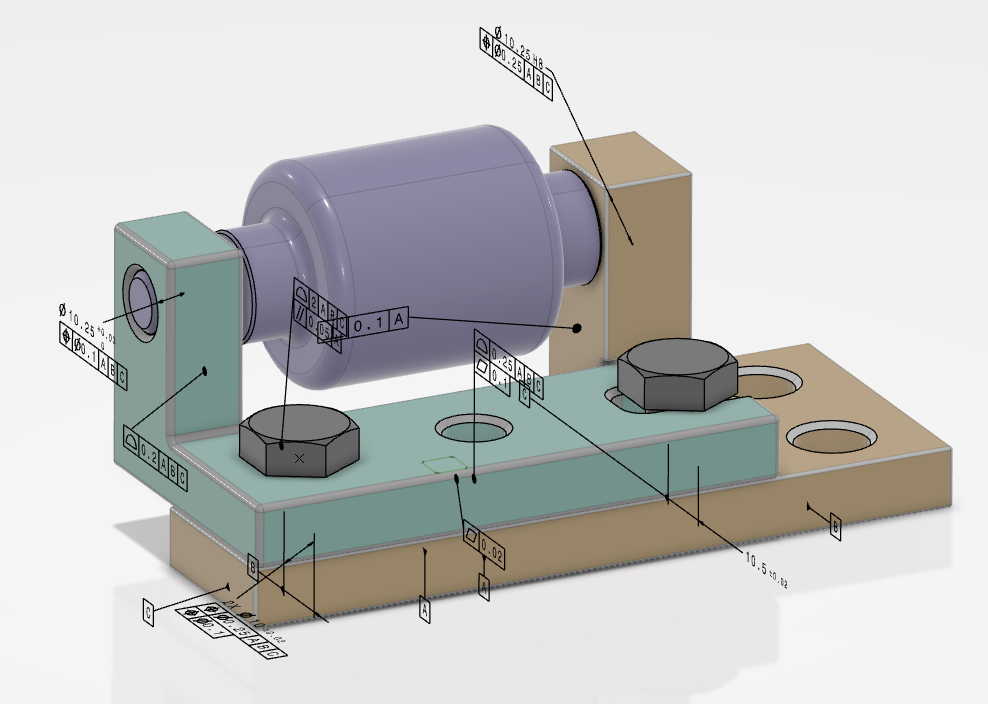

DCS offers starter and advanced courses in GD&T to get your team up-to-speed and applying GD&T concepts. Need help with your current drawings? DCS experts can help consult, train, and mentor your team to stay on target and achieve superior results.

DCS software solutions drive Model Based Enterprise by supporting Design for Manufacture and Assembly (DFMA) and Quality Management initiatives in industries including automotive, aerospace, medical device, high-tech electronics, and industrial machinery. DCS software solutions are leveraged daily by companies like Airbus, Boeing, Fiat Chrysler Automobiles, General Motors, LG, Nissan, Philips Medical, Samsung, Tesla, and Volkswagen. By leveraging simulation early in the product lifecycle, and applying Statistical Process Control SPC during production, manufacturers are improving product quality while reducing costs.

Join DCS this fall to see the new enhancements to 3DCS Variation Analyst, QDMWEB QI, and Metrologic Software solutions!

-- September 11th - Quality 360 - Connecting Design, Metrology, and Manufacturing PLUS AI Generative PMI with 3DEXPERIENCE

-- September 18th - What's New - See What's New in Metrologic's Universal Metrology Software

-- September 25th - What's New - NEW Kreon Scanning Technology Featuring Burton Precision

-- October 16th - What's New - 3DCS Version 8.2 Part 1

-- October 30th - What's New - QDMWEB QI 2025 Updates and New Features

-- November 13th - What's New - 3DCS Version 8.2 Part 2

Engineers can now view mean shift values for each individual contributor, offering more transparency into variation sources and allowing for more targeted process improvements.

Users can now automatically project multiple coordinate points onto calculated projected features in a single streamlined step—saving time and reducing the chance for manual error.

These advanced tools are now integrated into the standard Run Analysis window, alongside Monte Carlo and Contributor Analyses. Previously available only with an AAO license, they are now accessible to all users with a Variation Analysis license—making critical analysis capabilities more widely available.

Version 8.2 now includes Advanced Product Quality Planning (APQP) report generation within the 3DCS Automated Report. This new functionality simplifies compliance and documentation for automotive and other regulated industries.

Find out about the latest news, webinars, articles, and events from the DCS Blog.

Let DCS help with your next project to finish ahead of schedule

Let DCS help you complete your Dimensional Engineering project. By providing 3DCS modeling services, DCS helps manufacturers get their analysis results quickly so that important decisions about quality and design can be made early in the product lifecycle. Adding to this the ability to provide GD&T training, consulting, and drafting as well as Dimensional Engineering Consulting and process support, DCS offers a complete package of Dimensional Engineering Services.

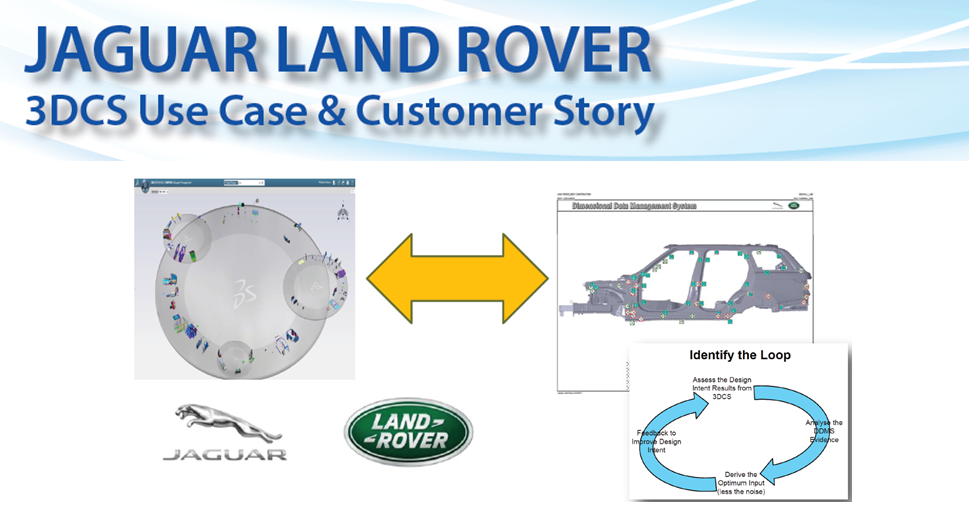

Closing the loop on quality by combining design and manufacturing

A closed-loop variation analysis process enables engineers to correlate the theoretical tolerance analysis results produced during simulation to the actual as-built results determined at other stages of the quality process.

DCS supports a closed loop by aligning the simulation power of 3DCS with the manufacturing visibility of QDM. Together, the Quality Intelligence system gives you the ability to support your entire PLM process.

DCS provides quality automation, data standardization, scan data analysis, real-time monitoring, and custom reporting for manufacturers

QDMWEB QI manufacturing quality management system gives you access to your quality information from anywhere, at any time, instantly. Using Quality Intelligence, QDMWEB QI automates your quality collection and helps reduce your costs with real-time monitoring and powerful SPC tools.

Gain Access to a Customizable System to:

DCS prides itself on providing step-by-step support for new and existing clients to help their initiatives succeed

DCS provides multiple support channels:

Why should you use DCS software tools?

3DCS and QDM support MBD and Model-Based Enterprise by optimizing designs and facilitating communication.

Learn More →

3DCS is the world leader in tolerance analysis and stack-up simulation. See how 3DCS provides real insight into your design and manufacturing.

Learn More →

QDM SPC Software automates manual processes to keep your team up-to-date on their quality and provides the tools to resolve issues quickly.

Learn More →

As an integrated 3D tolerance stack-up software, 3DCS opens as a new workbench in a familiar CAD environment, improving adoption, workflows, and efficiency.

Learn More →

Incorporate Finite Element Analysis - FEA - into your tolerance stack to address flexible parts and materials, spring back, forces, thermal, and operations.

Learn More →

QDM monitors your quality in real-time using dashboards, plant floor displays, and automated alerts to keep everyone informed and up-to-date on current production quality.

Learn More →

3DCS' unique assembly move - Pattern Move - allows users to simulate patterns of holes and pins to determine optimal settings.

Learn More →

Use 3DCS to design your product to fit and function from the ground up, reducing scrap, non-conformance, and rework at final assembly.

Learn More →

Use QDM to connect your supply chain, providing clear measurement plans and giving secure access to your system to upload reports and data.

Learn More →

3DCS provides tools to optimize and validate your GD&T to drive downstream processes and support Model-Based Definition.

Learn More →

3DCS simulates tooling, fixtures, and manufacturing processes to determine their effect on your assembly.

Learn More →

QDM is built from modules easily customized to your processes and environment. This makes QDM inexpensive to set up, and easy to grow over time. Utilize the Cloud for even more affordable options.

Learn More →

DCS is proud to work with leading manufacturers from across the globe

STELLANTIS |

AIRBUS |

LG ELECTRONICS |

GENERAL MOTORS |

THE BOEING COMPANY |

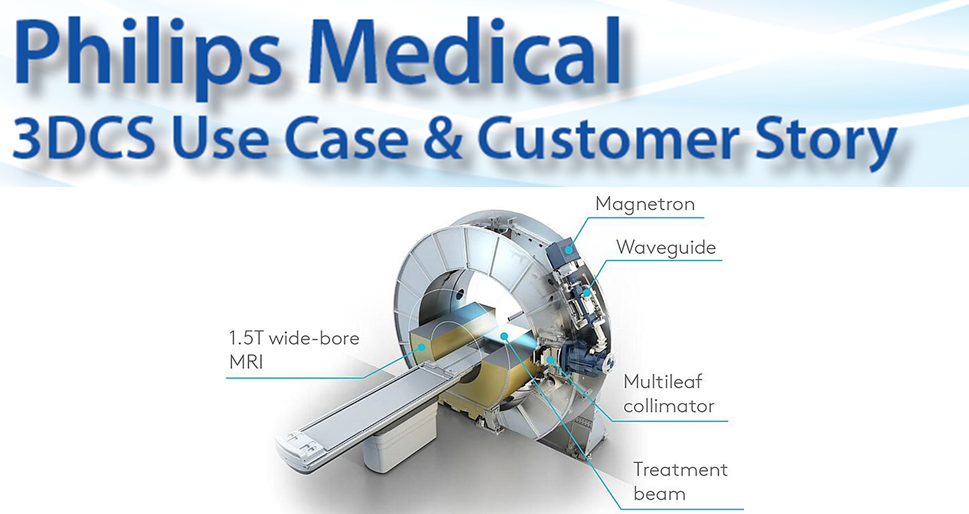

PHILIPS |

TESLA |

NIO |

MAGNA |

BMW |

EMBRAER |

SAMSUNG ELECTROMECHANICS |

JAGUAR LAND ROVER |

LOCKHEED MARTIN |

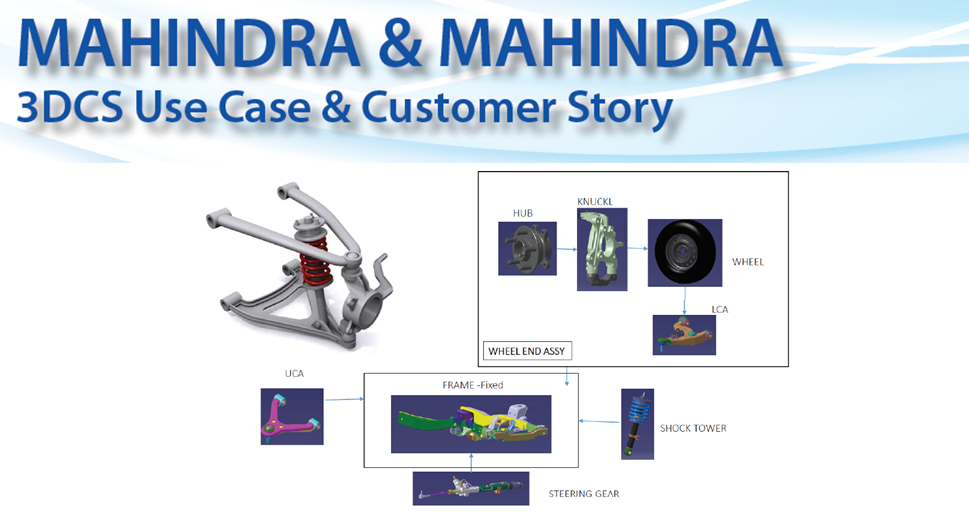

MAHINDRA |

AUTOLIV |

CESSNA TEXTRON |

MERITOR |

VALEO |

FAURECIA |

PETERBILT |

MCLAREN |

VOLKSWAGEN |

GE |

DAIMLER |

DURA AUTOMOTIVE SYSTEMS |

KENWORTH |

SONY |

GULFSTREAM |

TOYOTA |

NISSAN |

ELECTROLUX |

LEXMARK |

Laurence Allmark,

Senior New Product Quality Engineer, McLaren Automotive

General Motors

Daniel C. da Silva,

Embraer Tolerance Analysis Team Leader, Embraer

In a typical section of an A320 Family Aircraft, roughly 90 stringer couplings are installed. Around 2/3 can be covered with the parametric model (this equals 60...couplings.

In the A319, A320 there are 4 section joints, while the A321 has 6. One parametrical model can then cover 180 assembly situations.

Axel Siewert,

AIRBUS

Avery M.,

Design Engineer

Bob Haubrock,

Vice President, Product Engineering Software, Siemens PLM Software

See how other manufacturers are reducing their time to market while improving their yield and efficiency.

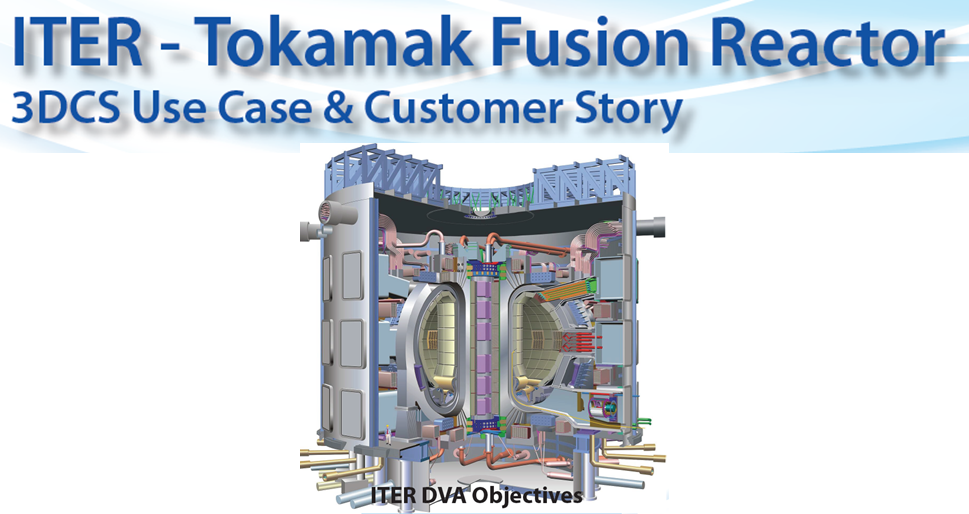

Tolerance Studies, Dimensional Engineering & Assembly Simulation on Fusion Energy Tokamak

Learn More →

Using 3DCS Variation Analyst and QDM SPC System for total quality control

Learn More →

3DCS Tolerance Analysis: Magnet Design for Elekta MR-LINAC

Learn More →

Effects of Dimensional Variations of Suspension Components on Vehicle Dynamics

Learn More →