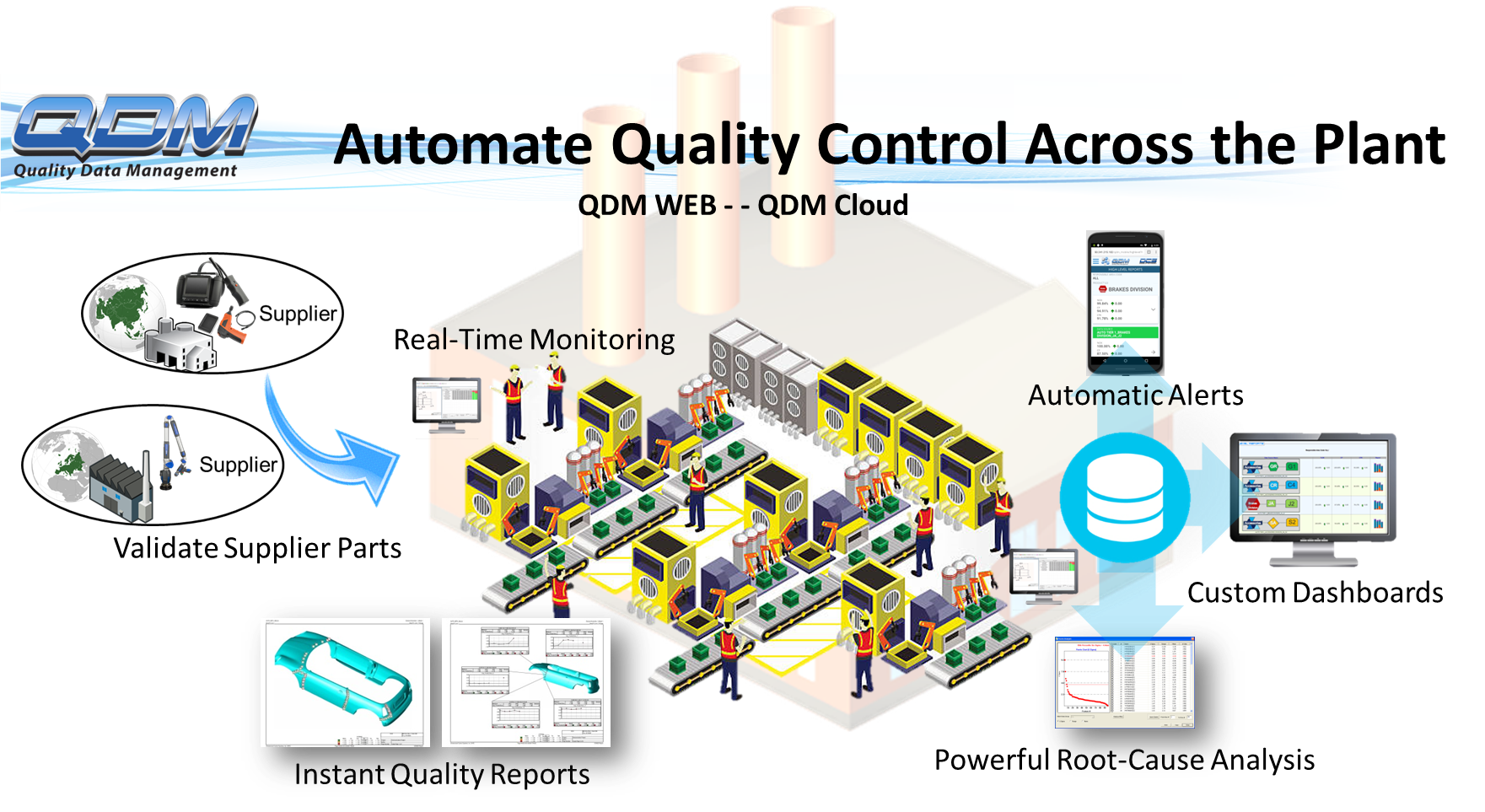

QDM SPC Platform provides the insight and tools you need to get ahead of your quality. Catch issues before they become problems, and solve them before parts are in the hands of your customers.

Empower your manufacturing with the same powerful SPC tools and quality management systems used by large enterprises but at a fraction of the cost. Utilize the Cloud to get up and running fast, and let DCS maintain your system. See all the benefits a QDM SPC Platform can bring to your organization.

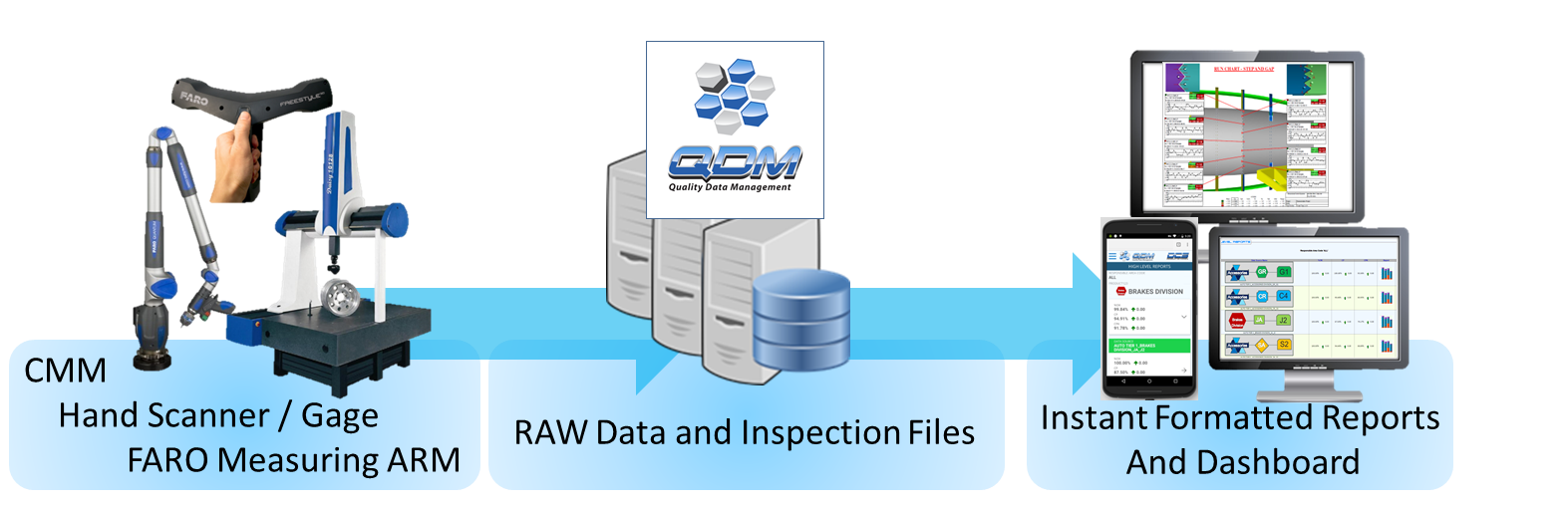

Stay Hardware Agnostic to Use Any Vendor

QDM uses translators to bring in data and outputs from any measurement or inspection device. This includes Excel sheets from manual measurements, as well as text and Excel outputs from CMM's, FARO arms, Hand Scanners, and vision systems.

Translators can be quickly configured for any data format, letting companies use custom outputs and native exports from their devices with a few clicks rather than having to reconfigure or reformat your data into a specific layout.

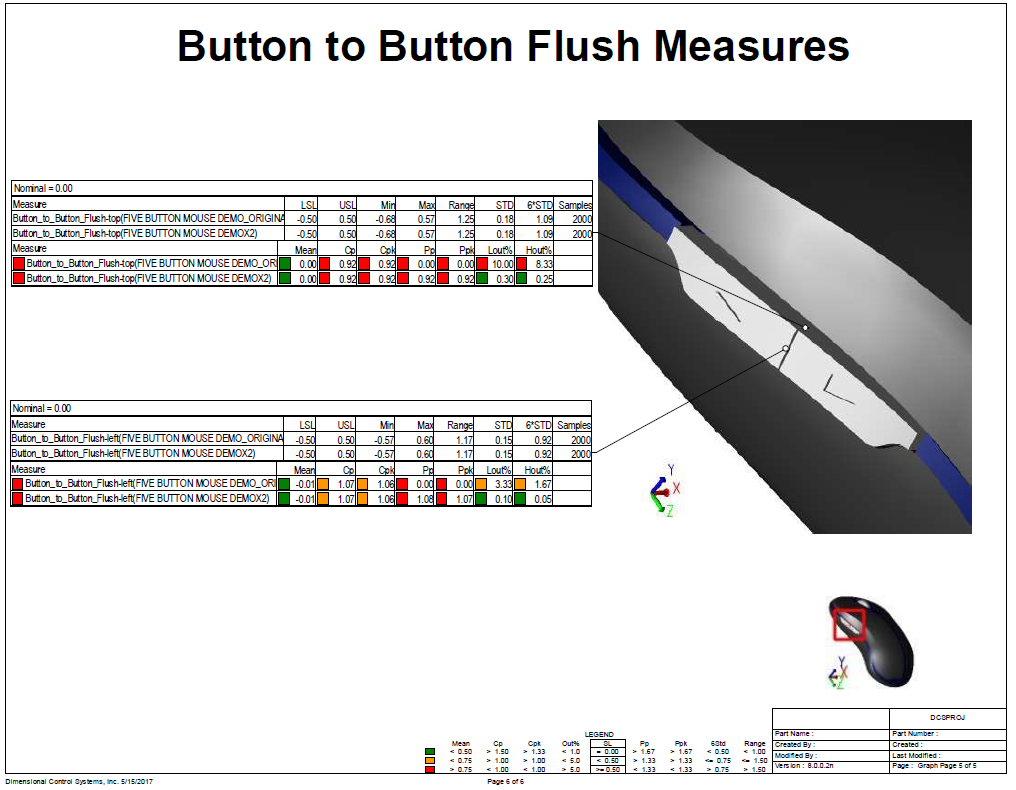

Instantly Create Quality Reports, Ppap's, FAIR's and SPC Results in Seconds

QDM ANALYST processes your data and creates statistical reports in seconds. As a QDM Stand Alone Module, QDM ANALYST can be used on its own or as part of a larger QDM SPC System.

Benefits to using QDM:

Use data and instant updates to support tolerance concessions and design changes

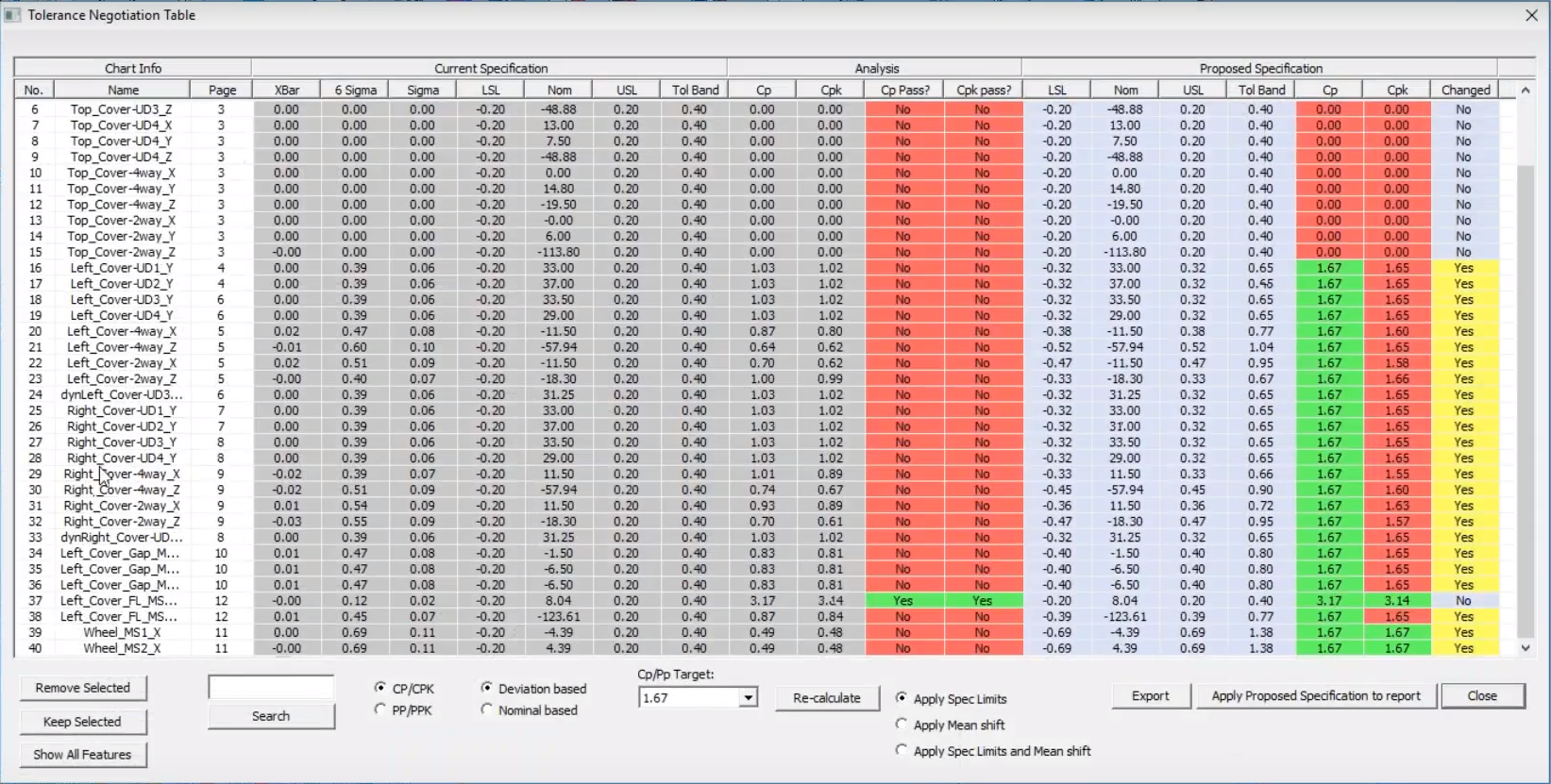

Tolerance Negotiator organizes all of your tolerances and shows whether they will meet given Cp, Pp, or specific metrics with their given values. By changing the targets, Tolerance Negotiator will show what values the tolerances will need to be in order to meet the given quality metric, demonstrating what is and is not possible to hold with the given design specifications.

This information is very helpful when discussing tolerances with customers and suppliers. With the ability to show why a tolerance may need to be loosened (increased range), clients and customers can better understand the reason, and negotiations can be based on data rather than opinion.

Give universal access to your team and suppliers for uploading data and collaborating on quality

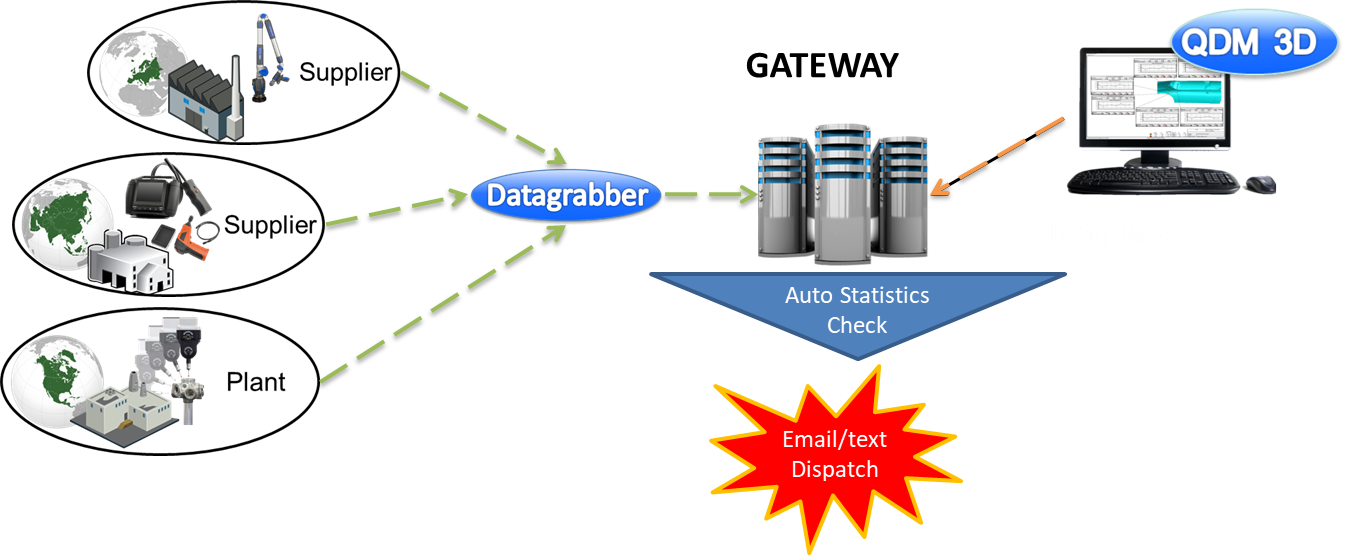

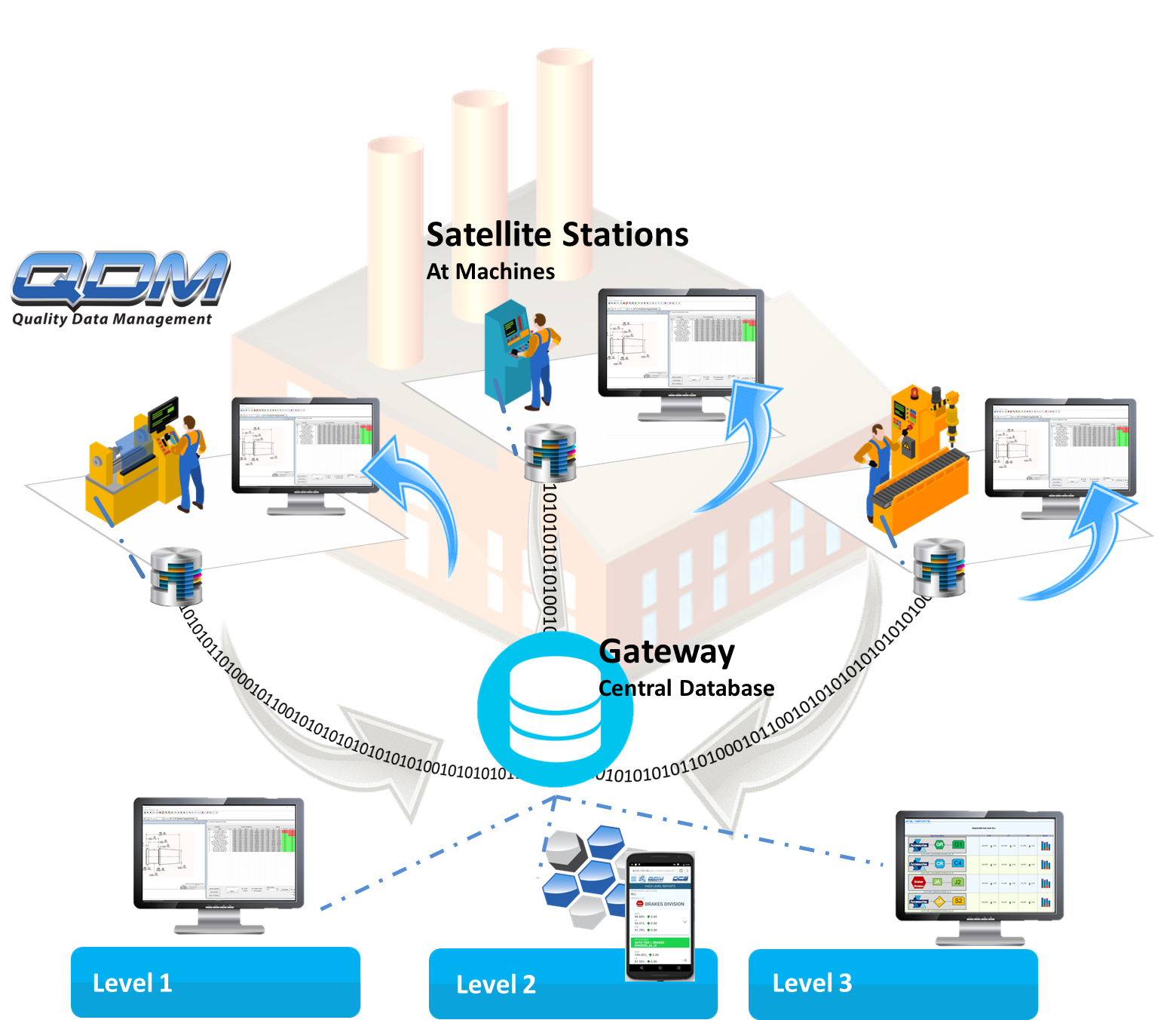

A QDM Gateway acts as the central hub of a QDM System. Installed either locally on a server or through the cloud, the QDM Gateway is the database repository of all of your information, standardized into a single format for easy access and use. As part of a basic QDM System, the QDM Gateway connects all of your QDM Modules together and allows you to automate processes to save time and get you the information you need when you need it.

Key Features:

Never be caught unaware with customizable triggers for automated warnings when problems start

Real-time alerts allow proactive correction of errors before they can affect the wider production.

QDM can generate and send email and text message alerts for various background events and triggers without user interaction. These are all set by the user or the administrator with specified triggers. This lets each user configure triggers and alerts based on processes key to their responsibilities.

Some Example Alert Criteria:

When the triggers activate, all users who have added the data set to their watch list will be notified. The system monitors all system functions, letting triggers be set to a variety of different system functions and whether to receive text or email alerts.

Create displays at each machine, station, or over the plant floor to show real-time measurement results

Satellite Stations update in real-time with measured data from the shop floor or inspection data. This informs your team of minute-to-minute changes in quality and allows them to react instantly to possible quality issues.

Companies often set up individual stations at each machine or process station so that the operator can see the quality specifications of each manufactured part and assembly as it is being completed. This allows for instant correction of identified issues, and with the CAD model or drawing being used for context, the operator can quickly identify the feature or area where the issue is located and begin corrective action.

Placing displays on the manufacturing line for the floor operators can give the team insight into their part-by-part quality. Using inline measurements or piece part CMM measurements, the display will update in real-time as the measurements are taken with trend charts, pass/fail color coding, and computed metrics, comparing all to set specification limits and notifying the floor when trends begin approaching an upper or lower limit, or when parts fail to meet objectives. This keeps your team agile and able to tackle production problems early before bad parts are made or the line has to be shut down.

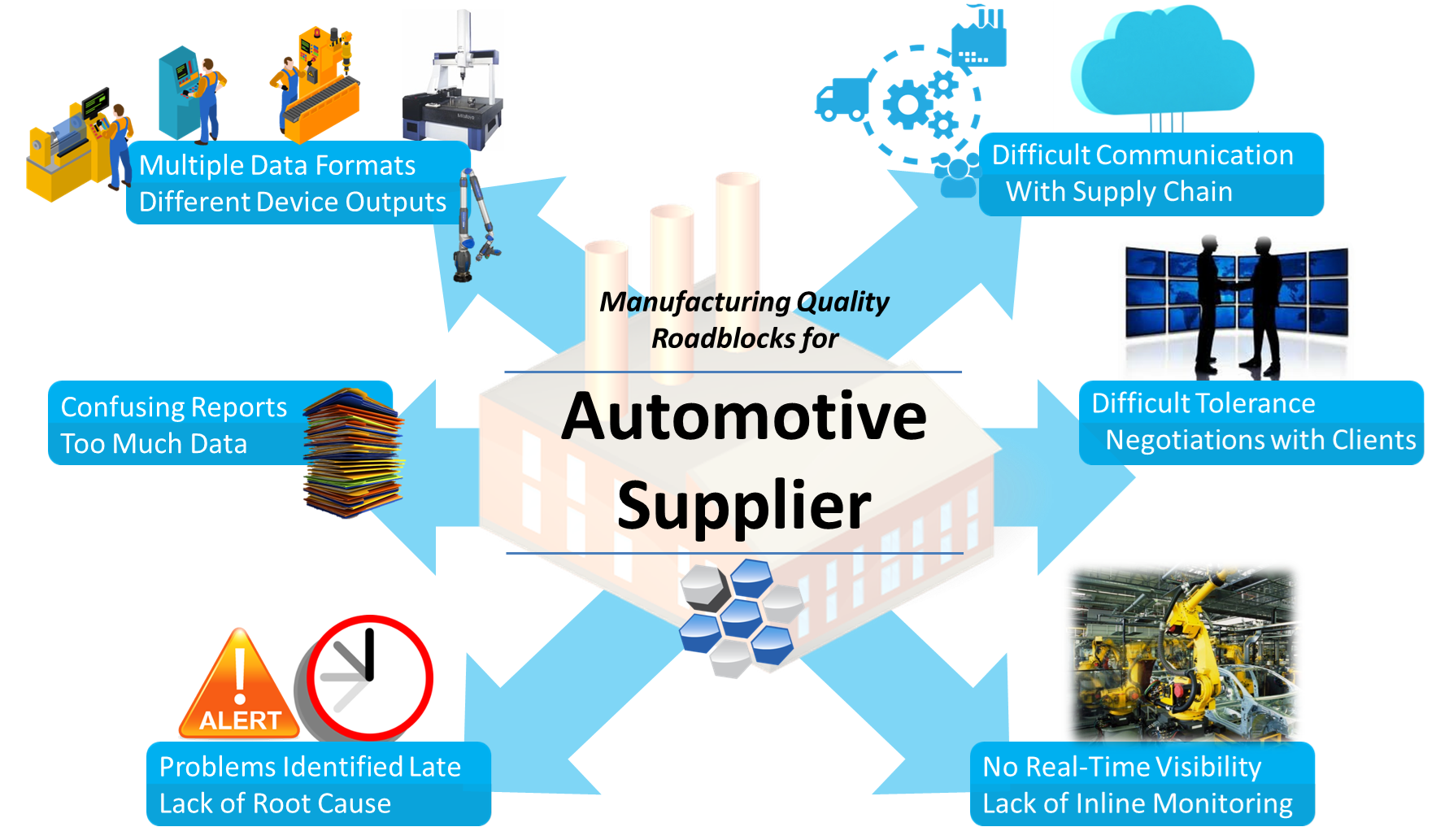

QDM solves many common issues facing manufacturers today

Your data is secure behind your firewall or on the cloud protected by top-of-the-line security.

Stay hardware agnostic so your plants can use any vendor.

Get all your data in standardized formats so it is easy to understand and use for decision-making.

Configure QDM to fit your organization, not the other way around.

Stay up-to-date with dashboards and alerts that constantly refresh.

Connect your supply chain to your QDM SPC Platform to both let them check their quality, and to check the quality of supplier parts before they ship.

Log in from any secure web browser on any device - phone, desktop, laptop, tablet.

Use a combination of automated reports, custom reports, dashboards, and alerts to know everything going on in your organization and create a single source for quality information.