Plant Data Analyzer

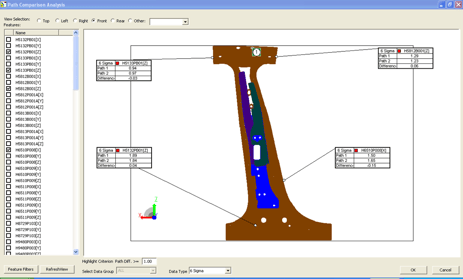

QDM PDA is an advanced analysis tool for diving deep into your data. As a QDM Stand Alone Module, QDM PDA can be used as part of a QDM System, pulling custom data sets from the QDM Gateway Server or on its own by loading in data files.

Benefits:

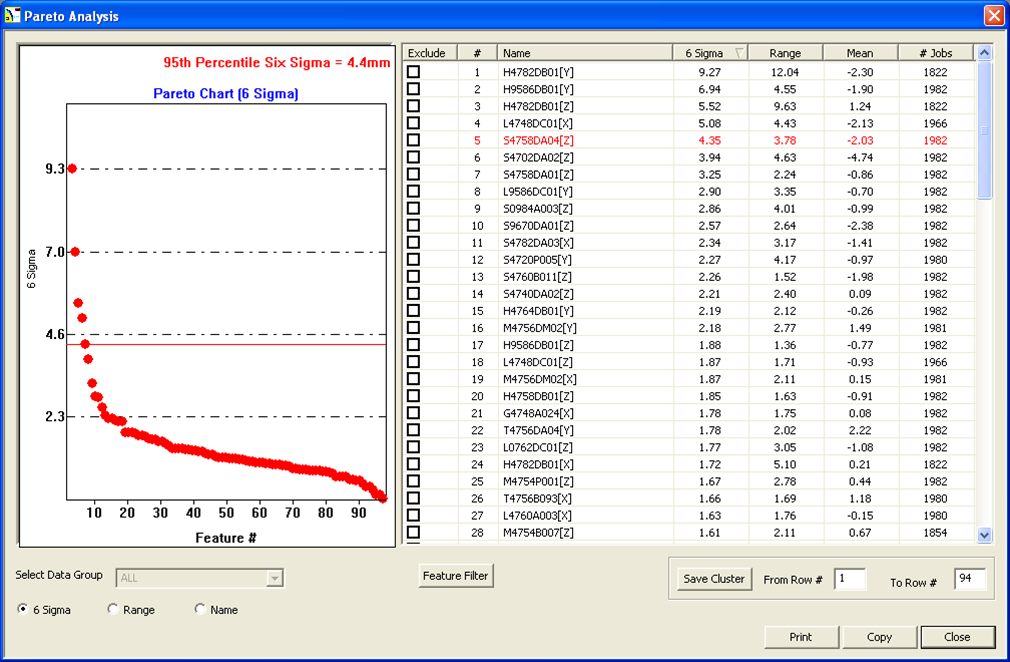

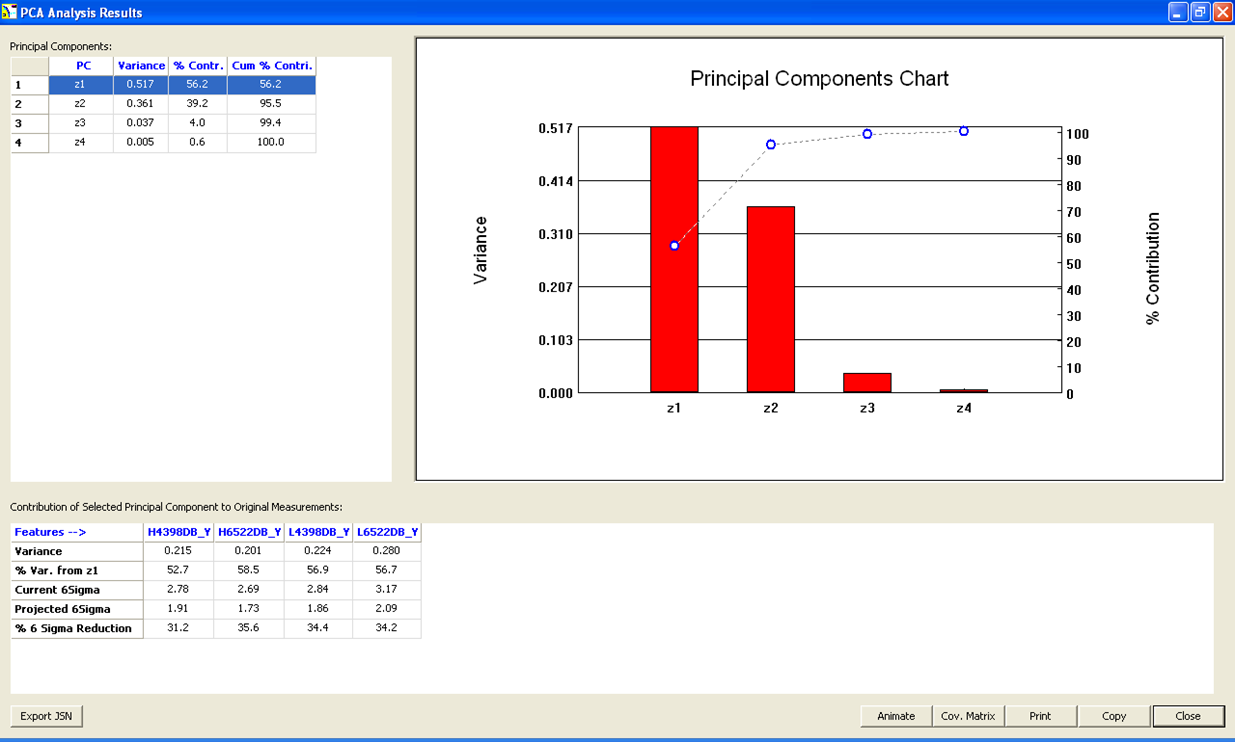

View the source of variation and quickly root cause the true root of the problem.

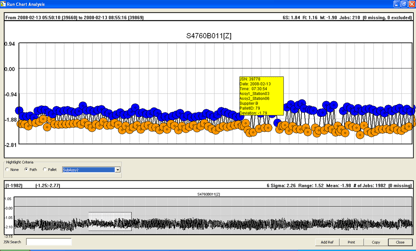

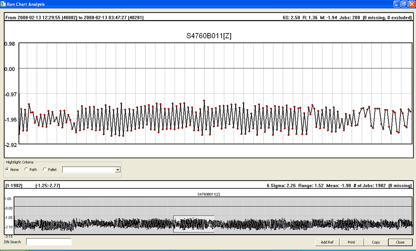

Quickly view the effect of a process change and how much variation it created or reduced. Quickly compare supplier A to supplier B to see how changing suppliers affected your product quality.

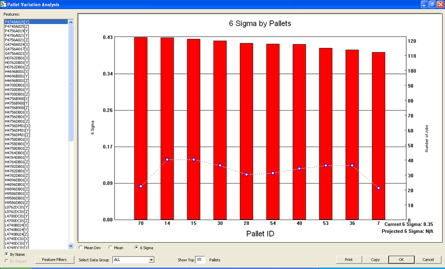

Zero in on the builds that use a specific carriage or fixture and compare and contrast that data to determine changes, variation and the effect on the overall build.

Analyze the data variation caused purely by fixture variation to quickly identify the fixture that needs to be corrected in an assembly line.

QDM PDA is an advanced analysis tool for diving deep into your data. As a QDM Stand Alone Module, QDM PDA can be used as part of a QDM System, pulling custom data sets from the QDM Gateway Server or on its own by loading in data files.

Value:

Find the source of production issues, and determine solutions.

Catch problems before they happen by finding trends and changes in the data.

Find out how changes to machines, processes, and tooling affect your production quality.