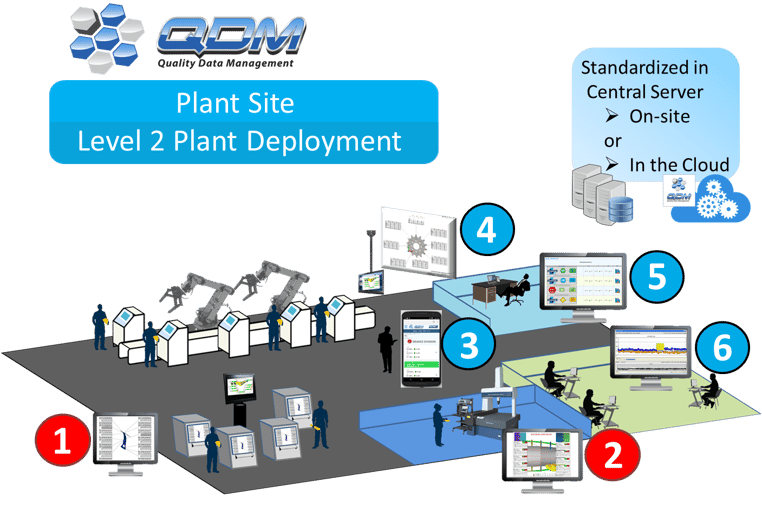

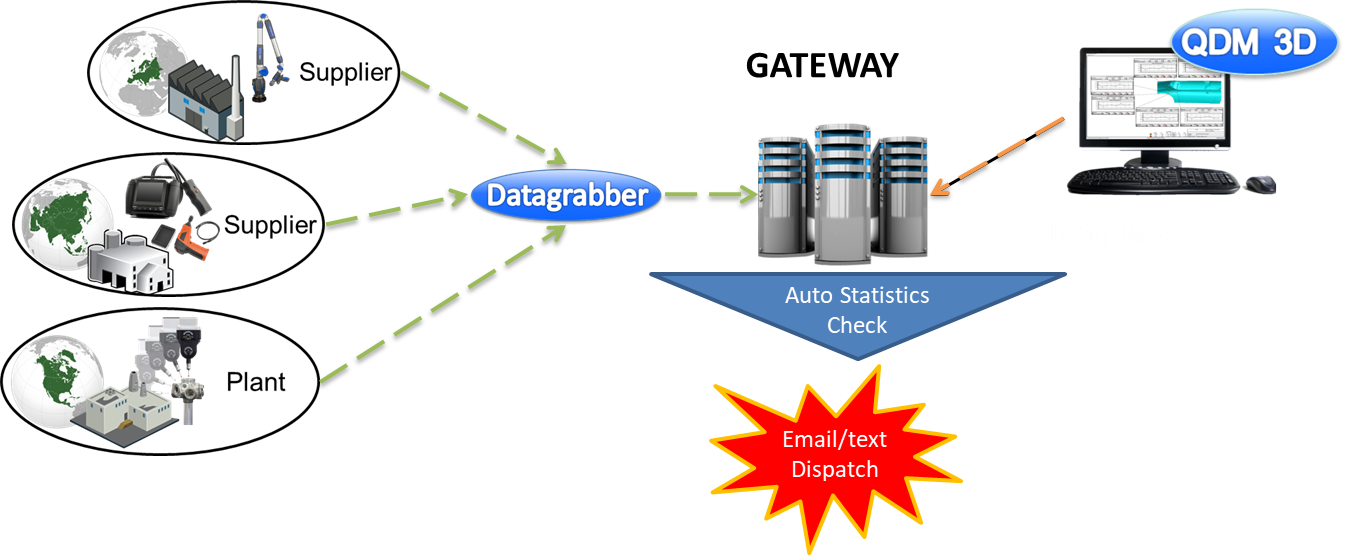

QDM SPC Sytems connect plants and suppliers to your central server, either on-site or in the cloud, and deliver actionable information for quality decision-making.

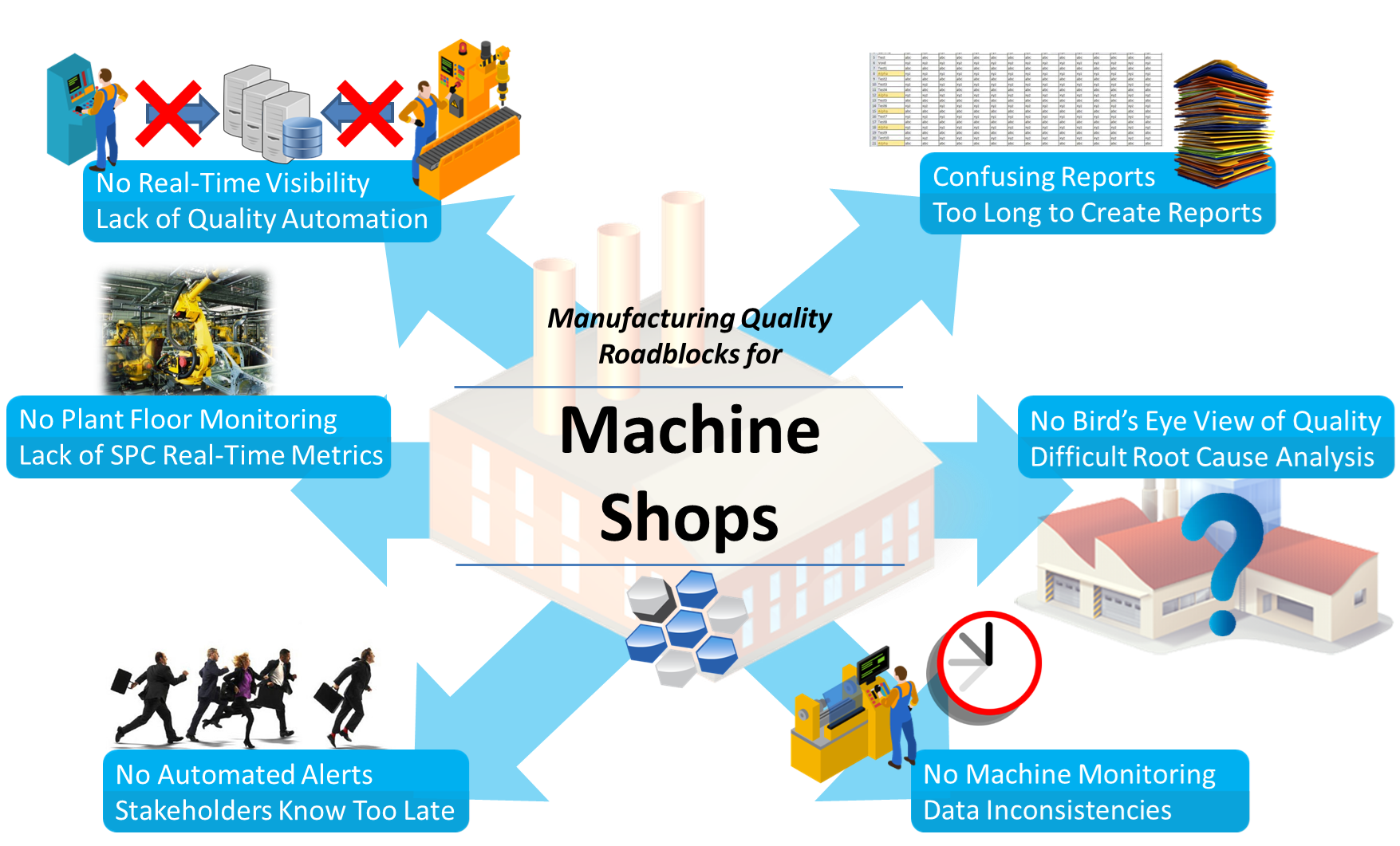

Many machine shops deal with similar problems with quality - lack of visibility, no plant floor visibility, no machine monitoring, too much delay in getting alerts, and too much data. Find out how a QDM SPC Platform provides a solution to these issues.

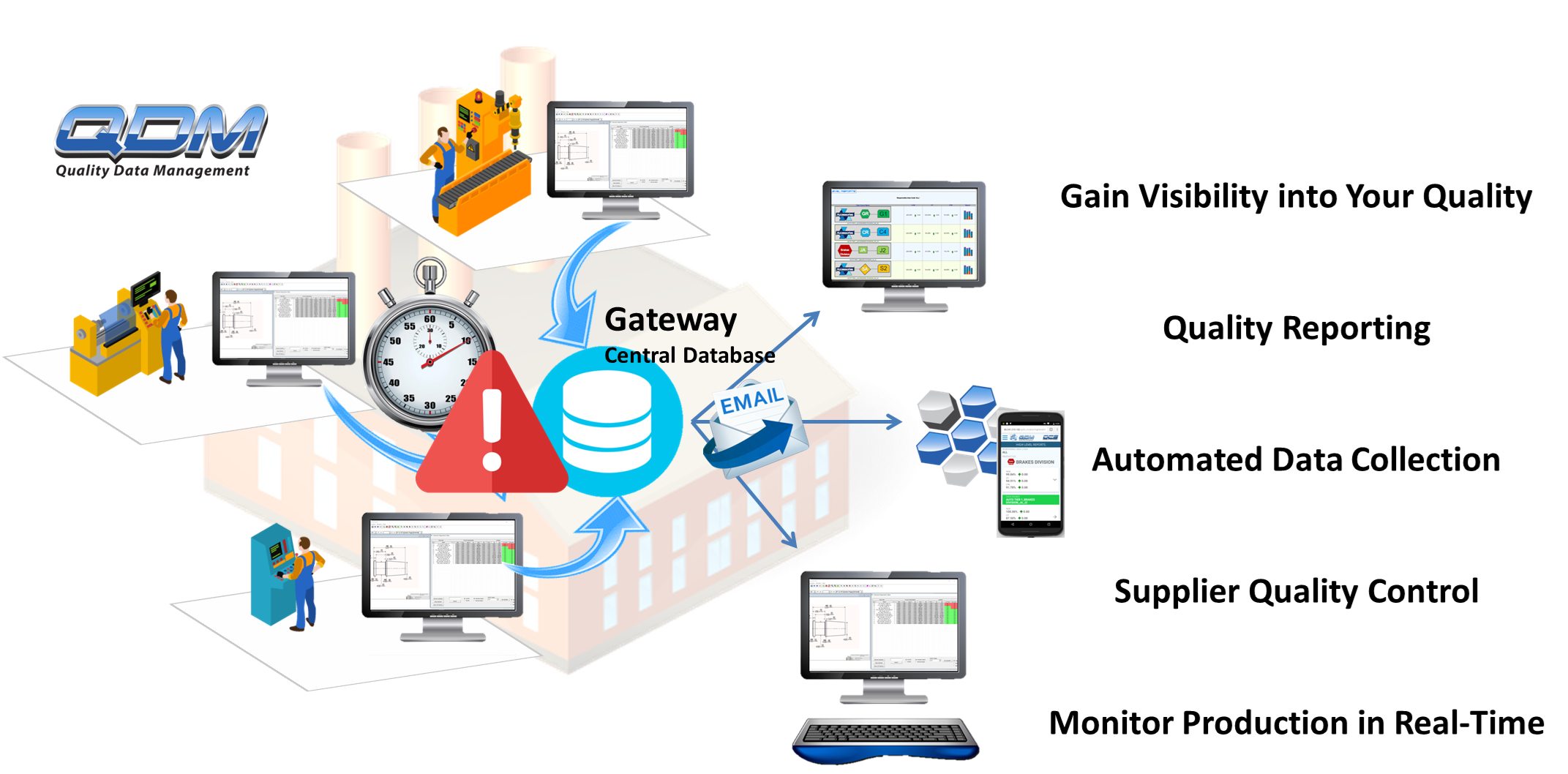

Automate data collection and processing

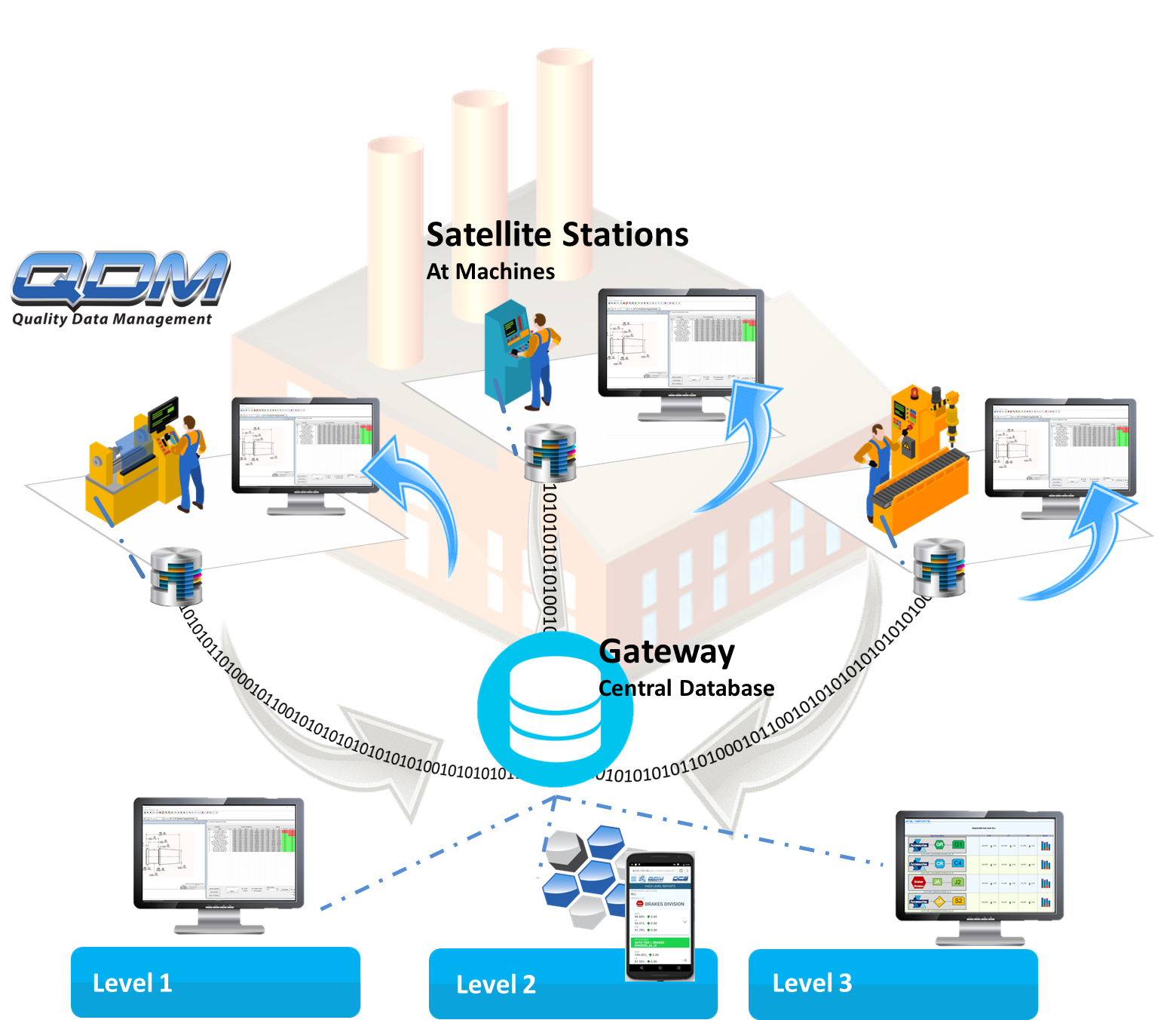

Data collection points throughout the plant can be automated to pull from machines and validate then store in a central database. That information can then be tapped to populate dashboards, reports and generate alerts.

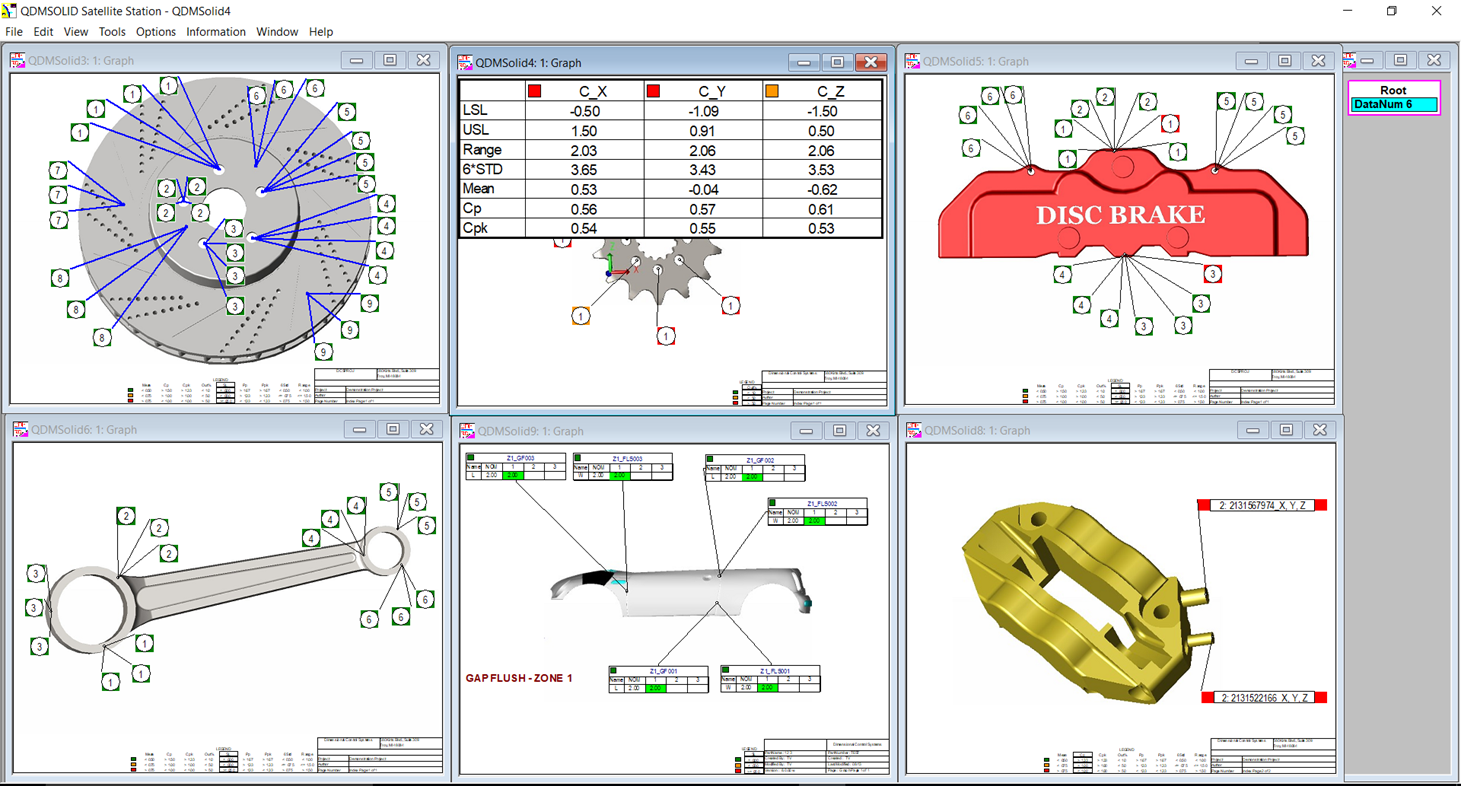

SPC Monitoring real-time quality

Satellite Station monitors can be set up throughout the plant with each station showing one or multiple graphical SPC reports. These satellite station interfaces are dynamic and interactive where a user can click on and drill down to any areas of concern to analyze the underlying data. Satellite Stations are helpful for providing visual and audio alerts on the plant floor when parts begin to trend out of spec.

Set statistical criteria for automated alerts

The system can be customized for each machined part with pass/fail criteria for individual critical dimensions that will in turn be used for generating automatic alerts as parts are measured. The alerts can be sent to users who have subscribed to the corresponding part data. These alerts take the form of audio alerts in the plant, visual alerts on the screen as well as email, and text message alerts as defined by the user.

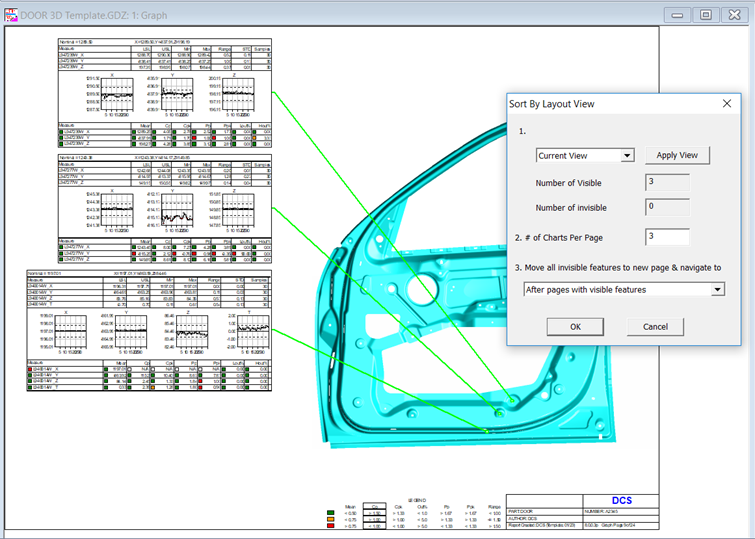

Use contextual information instead of stacks of charts and text boxes

Graphical reports provide instant context to users, providing important time savings for decision making and action. These reports are made from templates populated by shop floor data and published to the user community. The templates can be set up with powerful configurable SPC charts, and individually configured based on the part and process requirements.

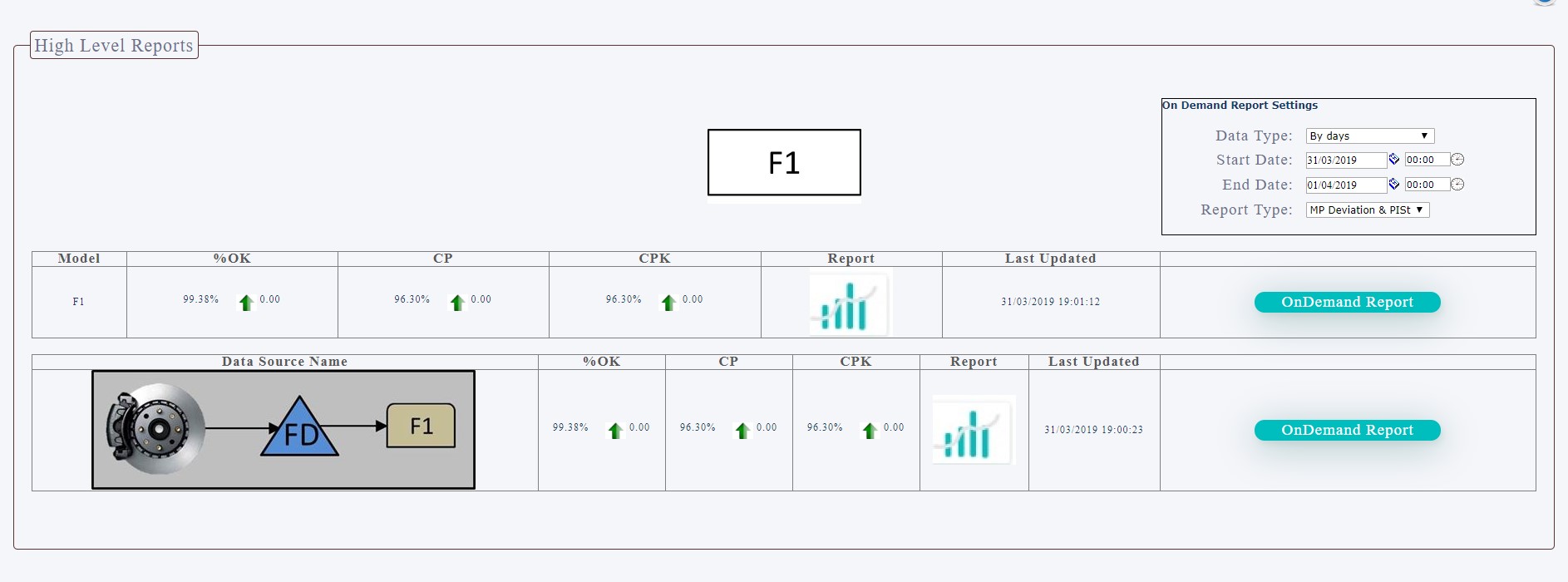

Get a bird's eye view of the machine status of the entire plant with clickable drill-downs and information

The system provides a web-based, anywhere access, to see the entire plant layout with the color-coded status of each machine and station. These dashboards are interactive which allows the user to drill down on any displayed status and get further information or generate custom reports.

Monitor each machine to verify that data is being collected and submitted according to schedule with time-based alerts

QDM Systems monitor process parameters to guarantee timely data collection is maintained. Each station and process is custom configured based on the preset data collection timetable. This provides a robust process monitoring interface by providing adequate alerts and reminders to the corresponding users to ensure data integrity.

QDM solves many common issues facing manufacturers today

Your data is secure behind your firewall or on the cloud protected by top-of-the-line security.

Stay hardware agnostic so your plants can use any vendor.

Get all your data in standardized formats so it is easy to understand and use for decision-making.

Configure QDM to fit your organization, not the other way around.

Stay up-to-date with dashboards and alerts that constantly refresh.

Connect your supply chain to your QDM SPC Platform to both let them check their quality, and to check the quality of supplier parts before they ship.

Log in from any secure web browser on any device - phone, desktop, laptop, tablet.

Use a combination of automated reports, custom reports, dashboards, and alerts to know everything going on in your organization and create a single source for quality information.