With more than 20 years of providing quality SPC and tolerance analysis solutions to manufacturers, DCS has been influential in helping manufacturers reduce their Cost of Quality

Beginning in 1994, DCS has been developing dimensional engineering and quality tools for manufacturers. With its start as an Engineering Service Provider, DCS has helped companies execute dimensional engineering to improve quality and reduce costs.

DCS was established by Robert Kaphengst and John Mathieson to support the need for a disciplined approach to GD&T deployment. This approach would come to be known as the Dimensional Engineering Process. The first DCS customers were automotive OEM’s and suppliers needing to apply this discipline to their engineering organizations.

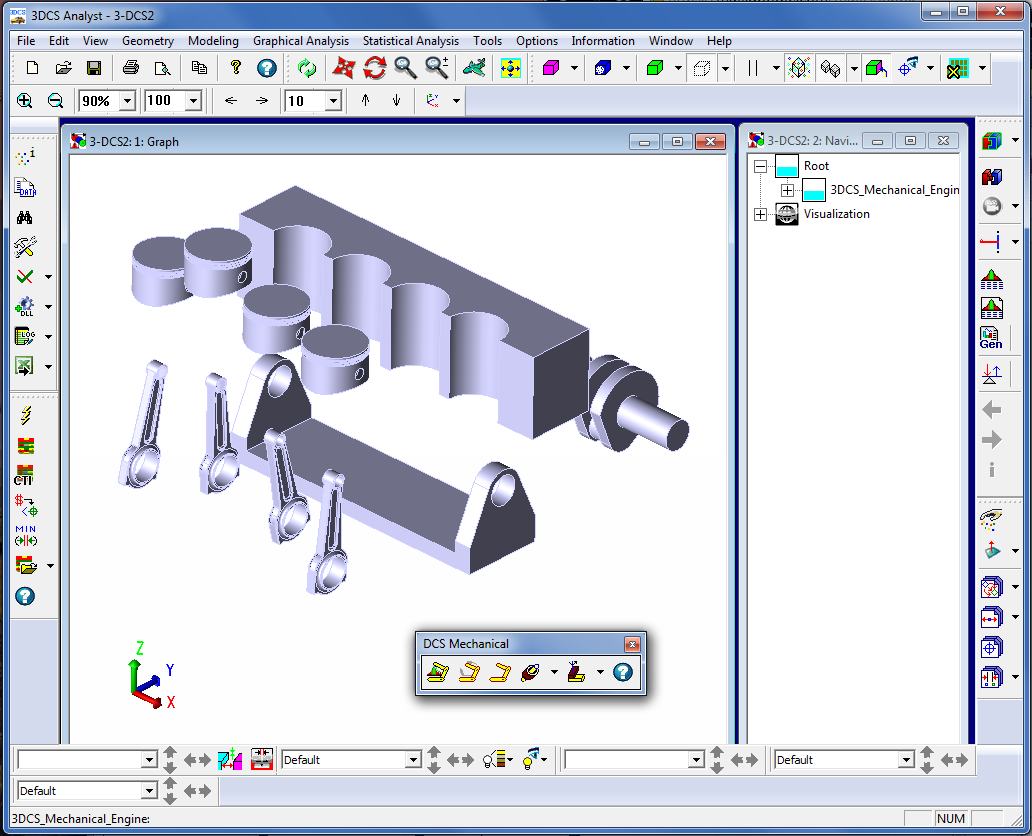

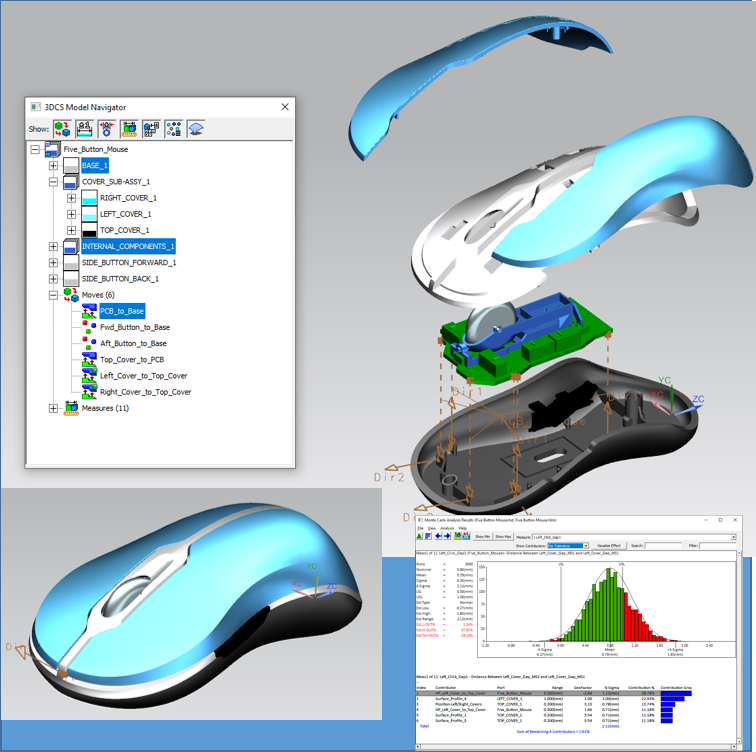

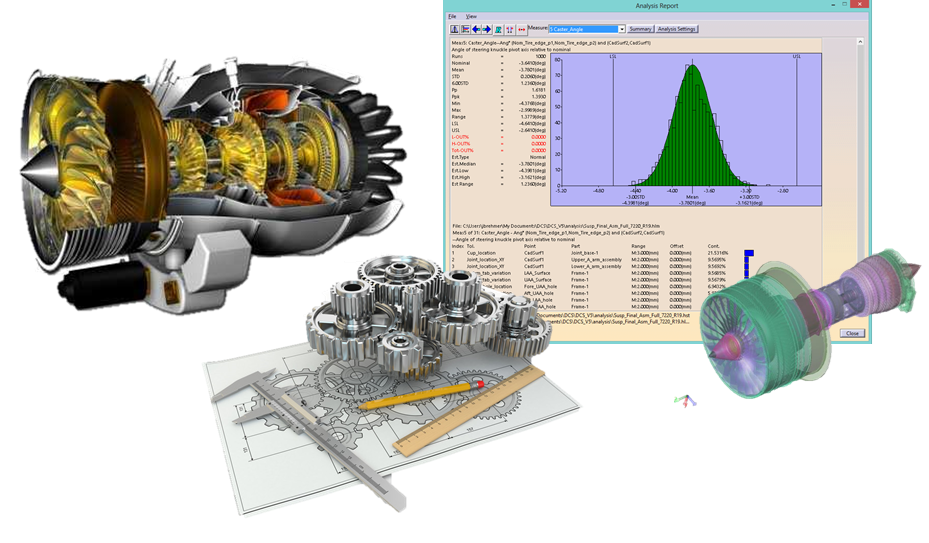

Release of version 1.0 of 3DCS 3-D CAD based Variation Analysis Software. Initially used to support its contracted dimensional engineering services work, 3DCS soon became commercialized and available to the general industry marketplace.

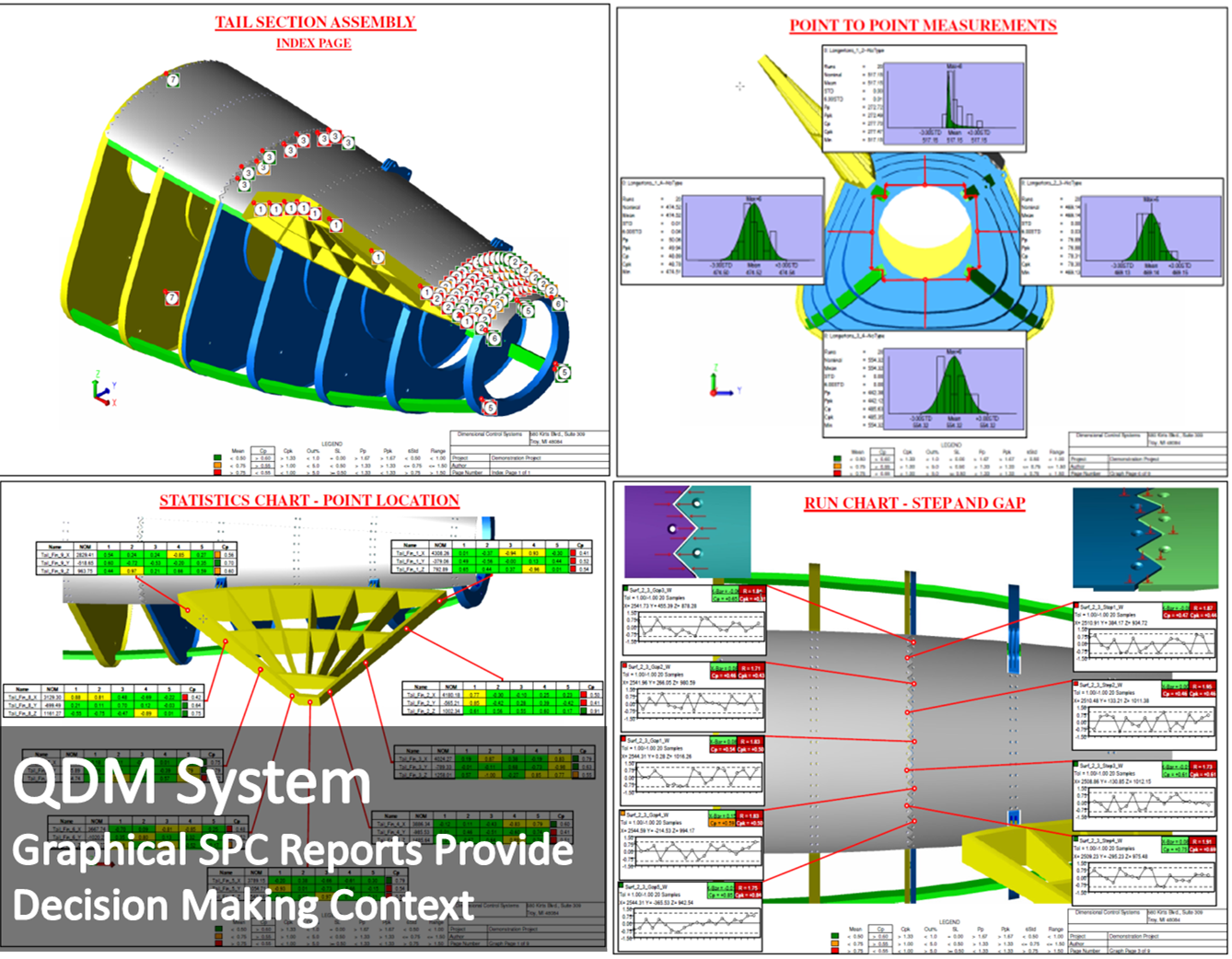

Originally called GDM, 1999 marked the release of version 1.0 of QDM Inspection Reporting software.

DCS enters into PLM provider Dassault Systemes CAA partner program. This leads to the development and commercial availability of 3DCS CAA V5 CATIA integrated variation analysis.

3DCS becomes integrated into multiple CAD systems through agreements with PTC (CREO), SIEMENS (NX), DASSAULT SYSTEMES (SOLIDWORKS), in addition to existing integrations in 3DEXPERIENCE and CATIA V5.

Sandvik acquired US-based Dimensional Control Systems (DCS) – a leading global provider of dimensional quality management software and on-site engineering services. DCS’s offering will complement and enhance Sandvik’s existing portfolio within metrology. The company will be included in the Industrial Metrology division, within the business area Sandvik Manufacturing and Machining Solutions. Click to learn more

Ulicny has been with DCS since its inception in 1994. Having worked with John Mathieson for 32 years, Ulicny’s background and over 30 years of experience in the dimensional engineering field have prepared him to take on this new role. As the future brings Sandvik and DCS together, Ulicny will be core to strengthening this connection and helping see the metrology division’s vision of a combined solution come to fruition.

To change the way businesses execute Quality Assurance by combining engineering methods with software technology and excellent customer service.

Dimensional Control Systems Inc. (DCS) based in Michigan, USA is focused on the methodology of Dimensional Engineering. DCS offers best-in-class software solutions and services to manufacturing companies the world over. With over 50 years of Dimensional Engineering background, DCS continuously strives to exceed our customer's expectations for world-class Variation Analysis and Quality Management System (QMS) software and services.

Customers

Users Worldwide

Countries

DCS develops the leading tolerance analysis software, 3DCS Variation Analyst, used across the world to reduce scrap, rework, and warranty issues. As a CAD integrated tolerance simulation, 3DCS is available in CATIA V5, SOLIDWORKS, CREO, NX, 3DEXPERIENCE, and as a standalone tool.

Automating quality processes and reporting, QDM is an affordable SPC System designed for complete customization to a clients quality processes. This gives company wide manufacturing visibility, allowing you to find and respond to manufacturing problems before they occur.

DCS offers its clients a variety of services to support their dimensional and quality initiatives. This includes modeling services, training, process consulting, and GD&T services.

With a dedicated team to providing qualified experts to support leading manufacturers, DCS prides itself on helping companies add new engineers to their teams quickly to temporarily increase their staff to handle large workloads and projects.

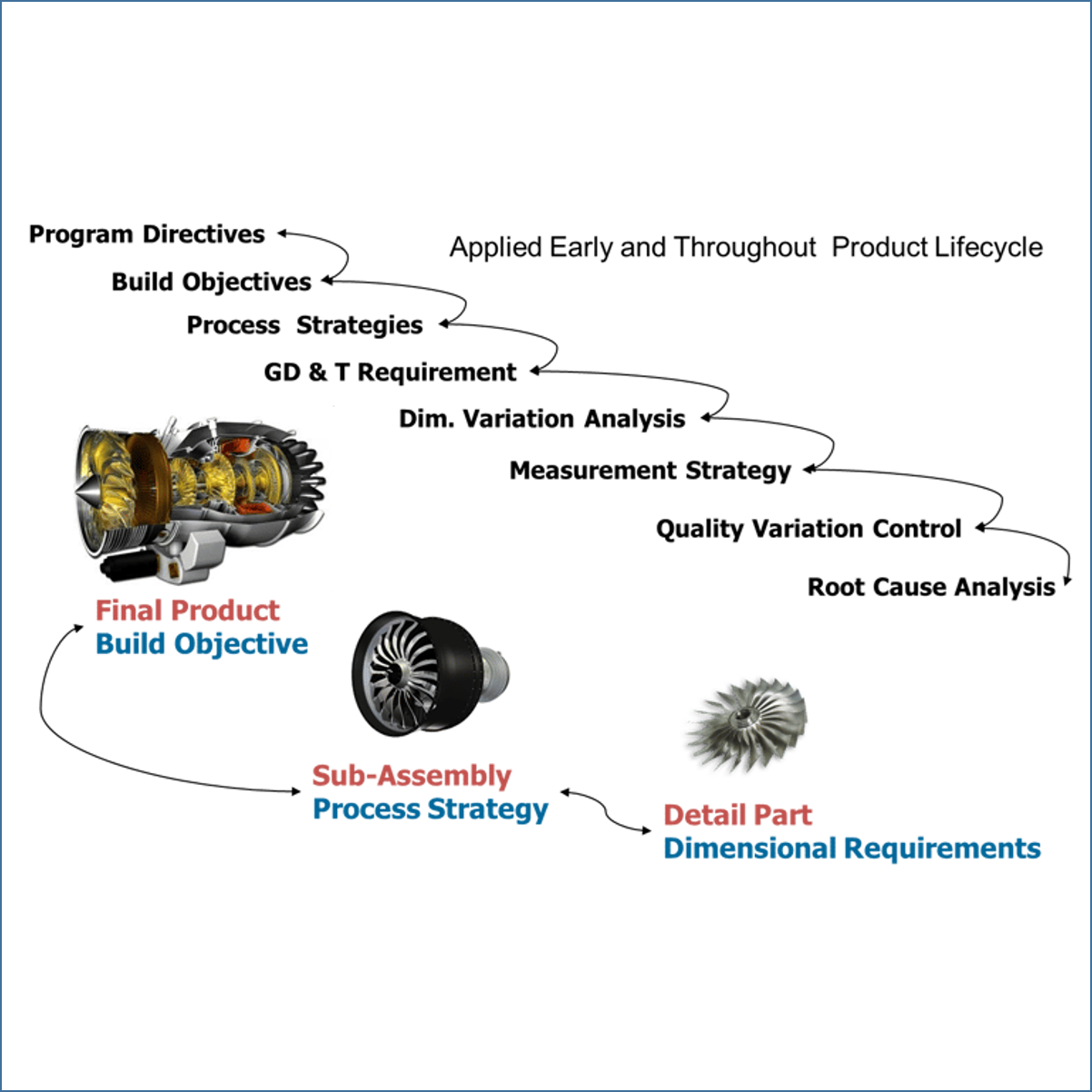

DCS exists today because we are passionate about the technology of Dimensional Engineering. As a company our mission at DCS, since the very beginning, has been to establish a work process and system of software tools to help engineers evaluate and ultimately select cost effective designs and processes that will in fact meet their quality needs. Dimensional Engineering is, after all, the process of using dimensional quality goals to drive design process decisions.

John Mathieson, Former President and Founder of Dimensional Control Systems, Inc.

Bob Haubrock,

Vice President, Product Engineering Software, Siemens PLM Software

In a typical section of an A320 Family Aircraft, roughly 90 stringer couplings are installed. Around 2/3 can be covered with the parametric model (this equals 60...couplings.

In the A319, A320 there are 4 section joints, while the A321 has 6. One parametrical model can then cover 180 assembly situations.

Axel Siewert,

AIRBUS

General Motors

Avery M.,

Design Engineer

Laurence Allmark,

Senior New Product Quality Engineer, McLaren Automotive

Daniel C. da Silva,

Embraer Tolerance Analysis Team Leader, Embraer

Meet some of the many people at DCS working every day to deliver you the best possible experience.

Ulicny has been with DCS since its inception in 1994. Having worked with John Mathieson for 32 years, Ulicny’s background and over 30 years of experience in the dimensional engineering field have prepared him for this role.

Leading the 3DCS product team, Dave Johnson is instrumental in the development and application of 3DCS software.

As a Six Sigma Black Belt, Thagu Vivek guides the QDM development and deployment teams in SPC System application and installations.

Jason Brehmer is the first line of support at DCS, providing answers to clients modeling and support questions on Helpdesk, Livechat, as well as email and phone.

As an ASME Certified GD&T Trainer, Gary Bell is the primary demonstration engineer at DCS, providing modeling examples, support, and services for new clients.

As the leading member of the service and training team at DCS, Spencer Strouse is paramount to delivering completed variation models, GD&T support, and training classes to DCS clients.

With over 8 years at DCS and multiple years in the industry, Chris Peuterbaugh brings with him experience in metrology and design, combining both to provide unique solutions to customers.

Michael Pritchard helps provide tolerance analysis and SPC software solutions to manufacturers ranging from the smaller suppliers to large, multi-national OEM's.

With a diverse background in dimensional engineering, program management, and manufacturing, Steve Bannasch brings a unique combination of technical expertise, leadership skills, and knowledge of quality standards to the table. This deep background allows Steve to provide real insight to customers and powerful solutions to manufacturing issues.

With experience working across the world, Sathya Indragopal offers both his expertise and cultural knowledge to support DCS resellers in the APAC region.

John Sienkowski manages the extensive partner network used by DCS to resell software solutions across the globe. By utilizing this channel, Sienkowski has been paramount to DCS' global presence.

Providing licensing, installation, and operation support to customers, Marco Villegas leverages his many years of IT experience in supporting customers software and hardware needs.

With experience in recruiting, operations, management, and human resources, Angela Rotter brings together an array of skills to support the transition of DCS into a Sandvik company, while helping the day to day operations continue.

Experienced human resources representative with a demonstrated history of working in the staffing transportation and engineering industries.

Skilled in customer service, sales, communication, leadership, and interviewing. HR professional that graduated from Macomb Community College and continuing education at Northwood University.

Helping employees at DCS onboard and wade through the paperwork associated with new and continuing employment, Carrie Zink has been a helping member of the team at DCS since the beginning.

See what's happening at DCS from the DCS blog, Engineering Talk.