QDM Supplier Quality gives you the ability to create standardized forms that your suppliers can populate with their quality data. This communicates the measurement plan and points you want in an easy-to-understand format while giving your supply chain a simple and automated method of reporting their quality before sending any parts.

Benefits:

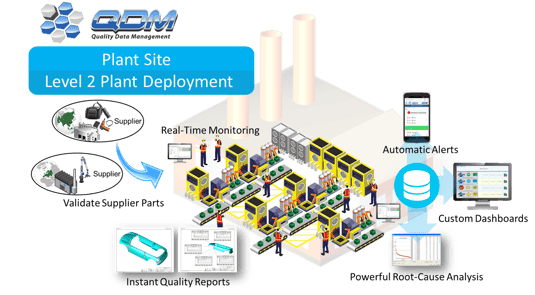

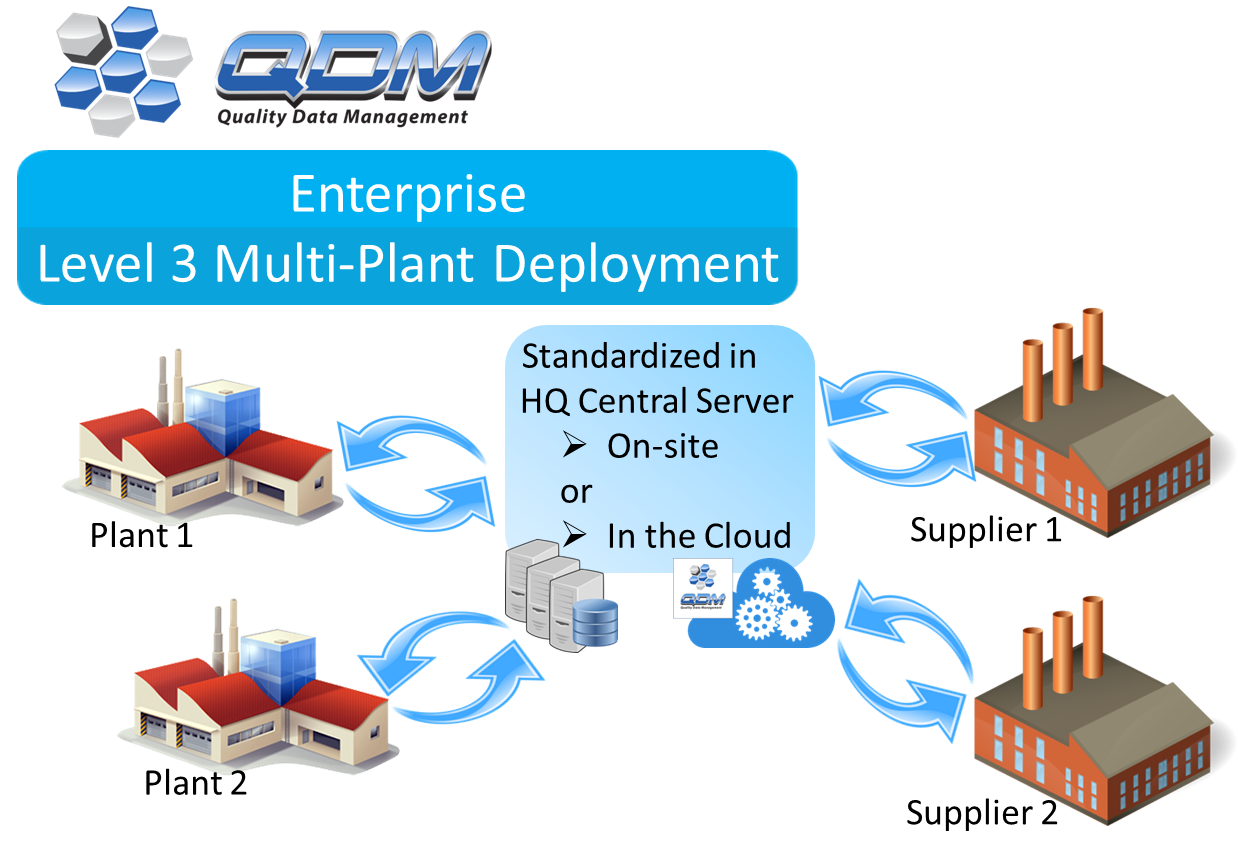

By connecting your supply chain to your quality data management process, you can accept or reject parts based on standardized measurements before they are sent. Correct supplier quality issues before receiving parts. Bring all of your suppliers' quality into a central database and create dashboards and reports for real-time monitoring, trend tracking, and statistical reporting.

Value:

use QDM to standardize your supplier data to make it easy to analyze, report, and compare. Provide limited access to suppliers so that they can view their quality data before sending parts, giving them time to find and fix any issues before shipping parts.

Learn More →

The QDM Platform can create automated supplier data collection or provide a web portal that suppliers can upload data to in order to quickly get information into the QDM system for OEMs and customers to view. Always know how your suppliers are performing before receiving parts.

Learn More →

QDM can give your suppliers the same quality visibility into their quality at a fraction of the cost. Allow your suppliers to monitor their own quality and resolve issues before sending parts to you, and making them your issues.

Learn More →