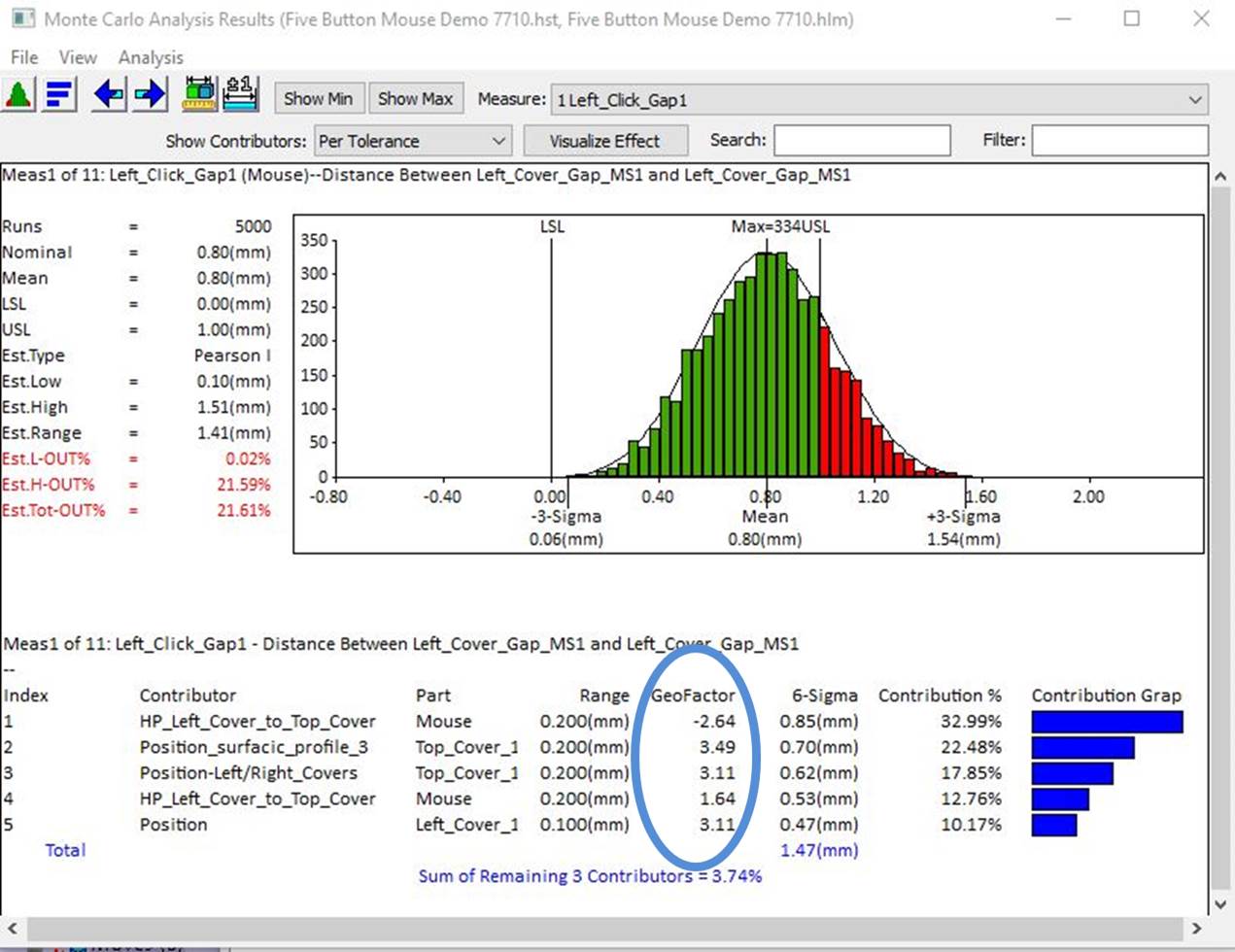

GeoFactor, built into 3DCS Variation Analyst, provides a clear understanding of how parts relate to one another and multiply tolerance changes because of assembly and part geometry.

Now Part of Core 3DCS Variation Analyst - No Longer an Add-on

GeoFactor Analyzer adds to your analysis results by determining the GeoFactor value for each tolerance.

Key Benefits

View the geometric effect of your tolerances. Based off of the geometry, determine how much the geometry amplifies or mitigates your tolerances.

Benefits:

View all GeoFactor values in your model in one window. Update your model information and see the effects instantly.

GeoFactor improves your analysis results to help you understand how the geometry of your assembly affects your tolerances. This is important when optimizing tolerances and understanding which tolerances are critical to your quality. Find out how to use GeoFactor to better understand your model's quality.