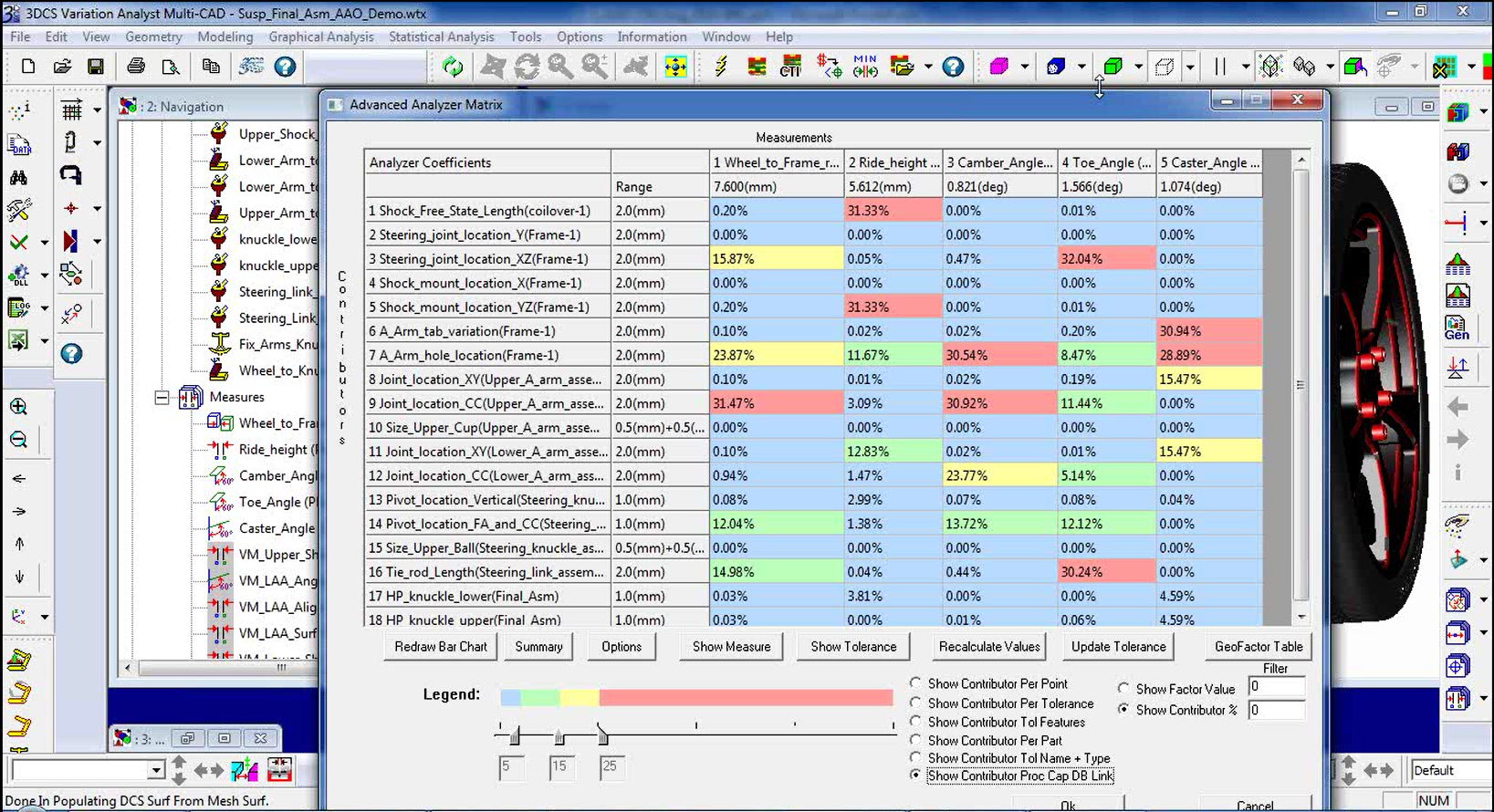

Use Advanced Analyzers to work with large models, validate moves, determine which part contributes the most variation and optimize tolerances based on set goals

Benefits:

Benefits

Simulation Based Sensitivity is the next stage in the advancement of 3DCS analysis. We can now see into 3DCS model behavior in ways not possible before. Besides the usual HLM lists, we now gain insight into multivariate interactions between inputs and their effects on output mean shift.

Use SBS when:

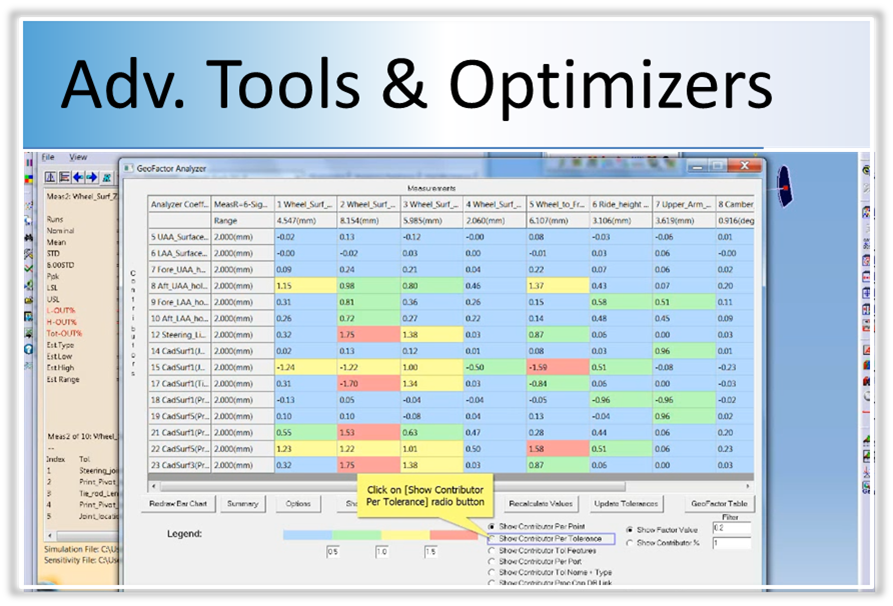

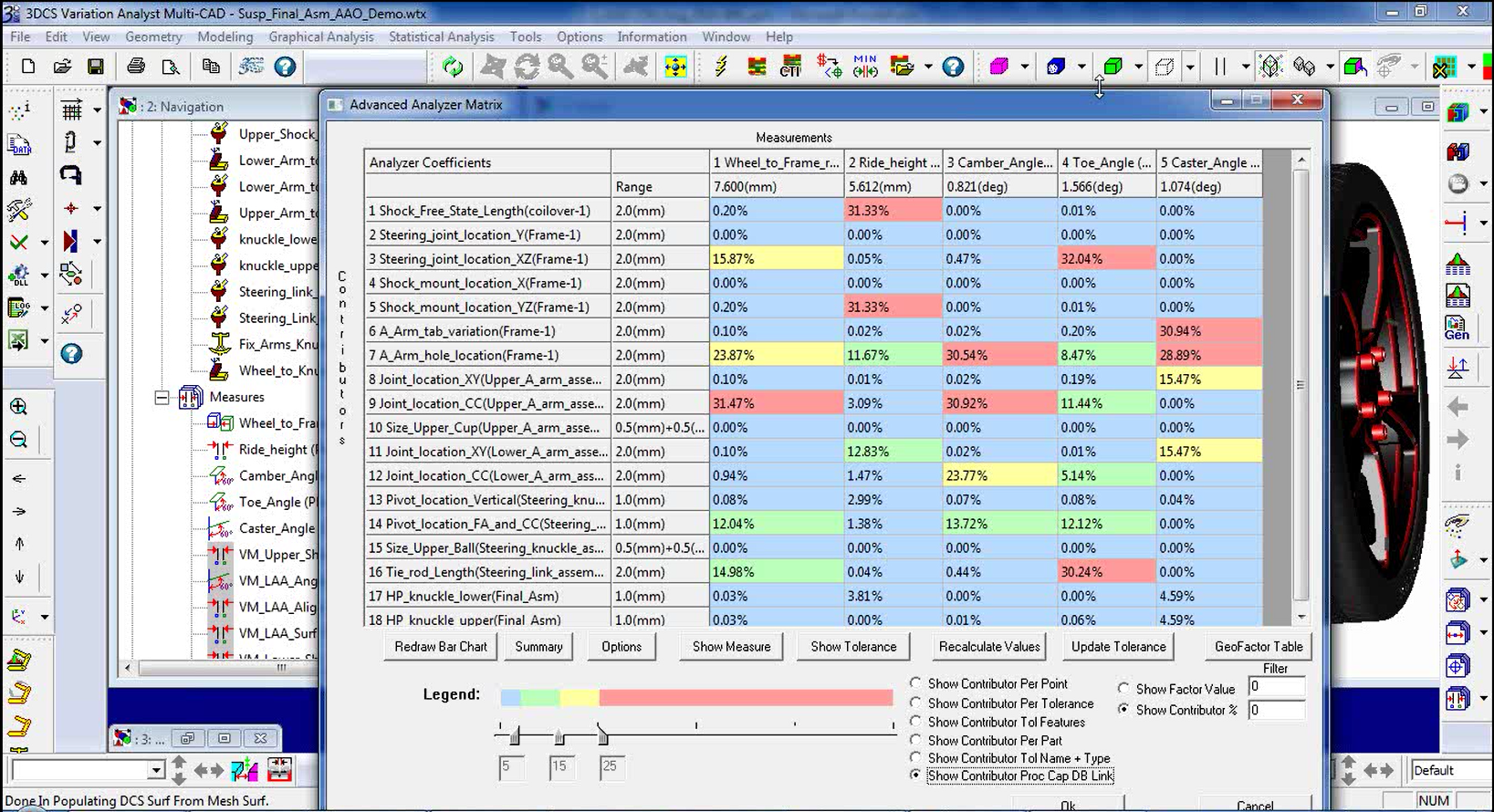

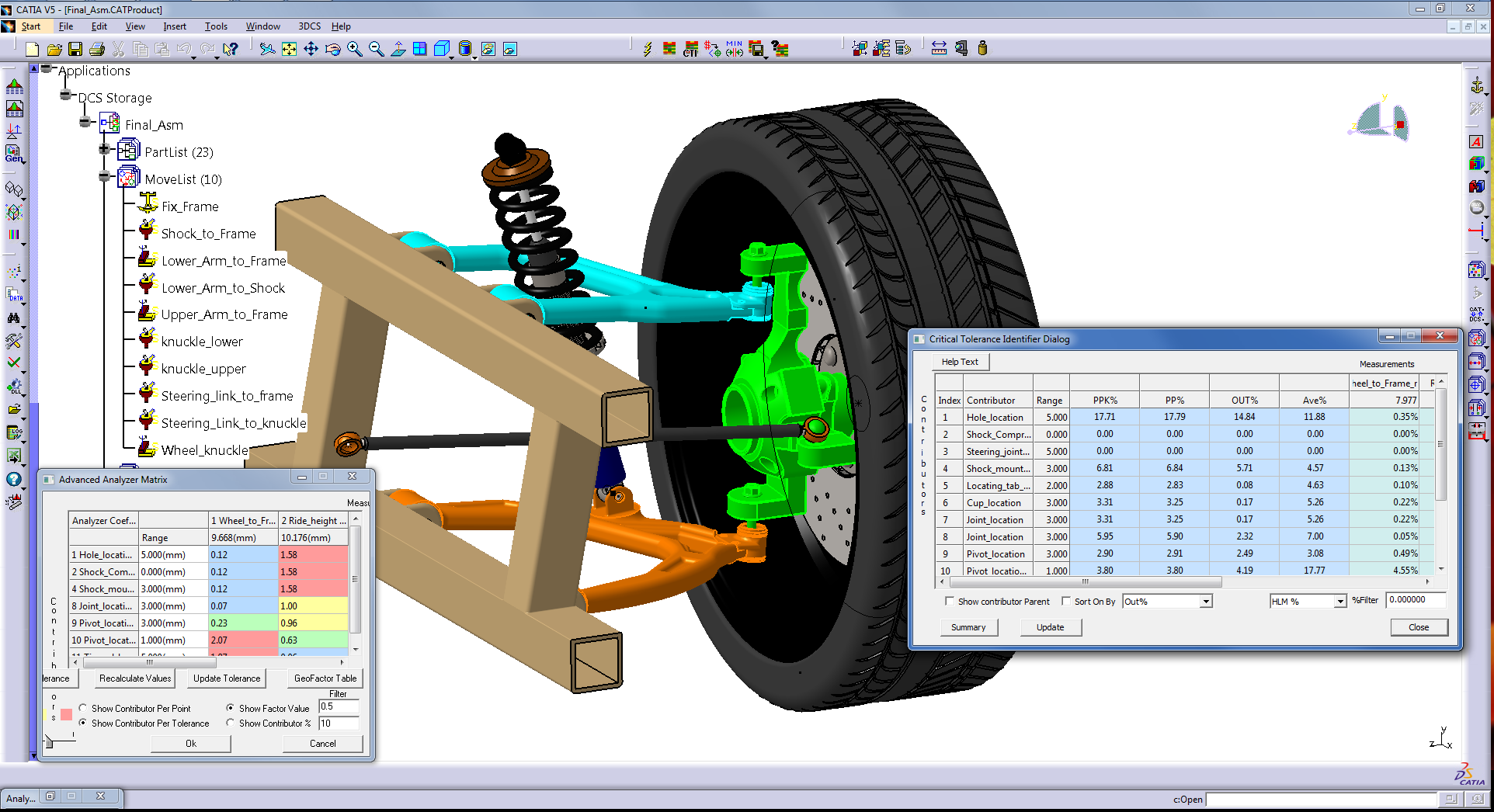

The GeoFactor Analyzer Matrix gives you the ability to see all of your measurements or tolerances in a single matrix. You have the ability to change parameters and inputs, as well as change tolerances in the matrix to instantly see the resulting changes.

Benefits:

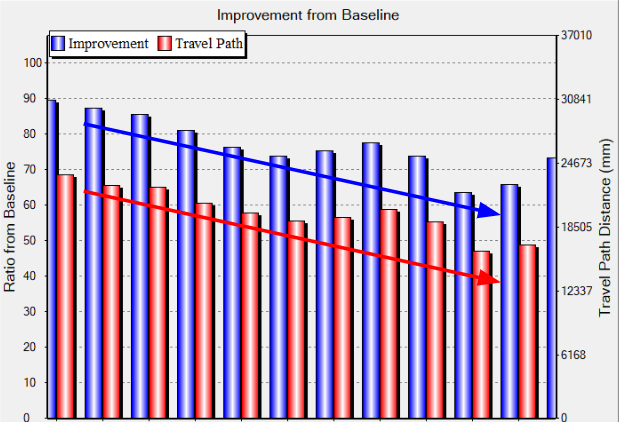

The Optimizers determine which tolerances are critical, and which are non-critical, and then increase non-critical tolerances to reduce manufacturing costs. This is a great method of taking general tolerances across an entire model, and optimizing them to have tighter tolerances on key features while opening (increasing) tolerances are non-critical areas, all with the push of a button. Not sure you want to keep the new tolerances? AAO only updates your model when you select the Push to Model button and update your model.

Benefits:

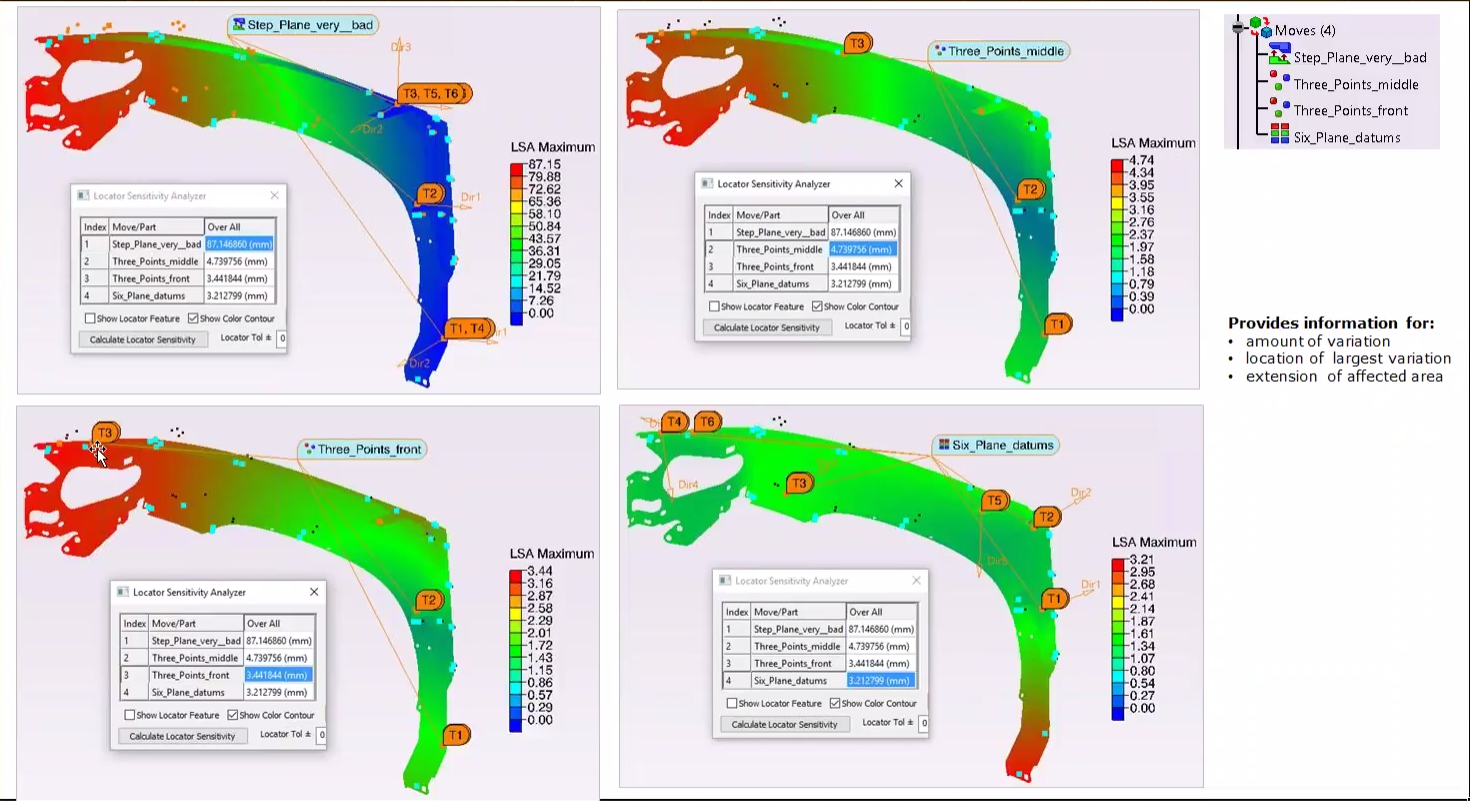

Use Monte Carlo simulation calculations to weigh the measures in the model to determine the percent contribution to the overall model. This determines your most critical measurements and tolerances, basically your largest contributors to variation across the entire model, instead of in relation to a specific measurement.

Benefits: