Gain trace-ability across your enterprise

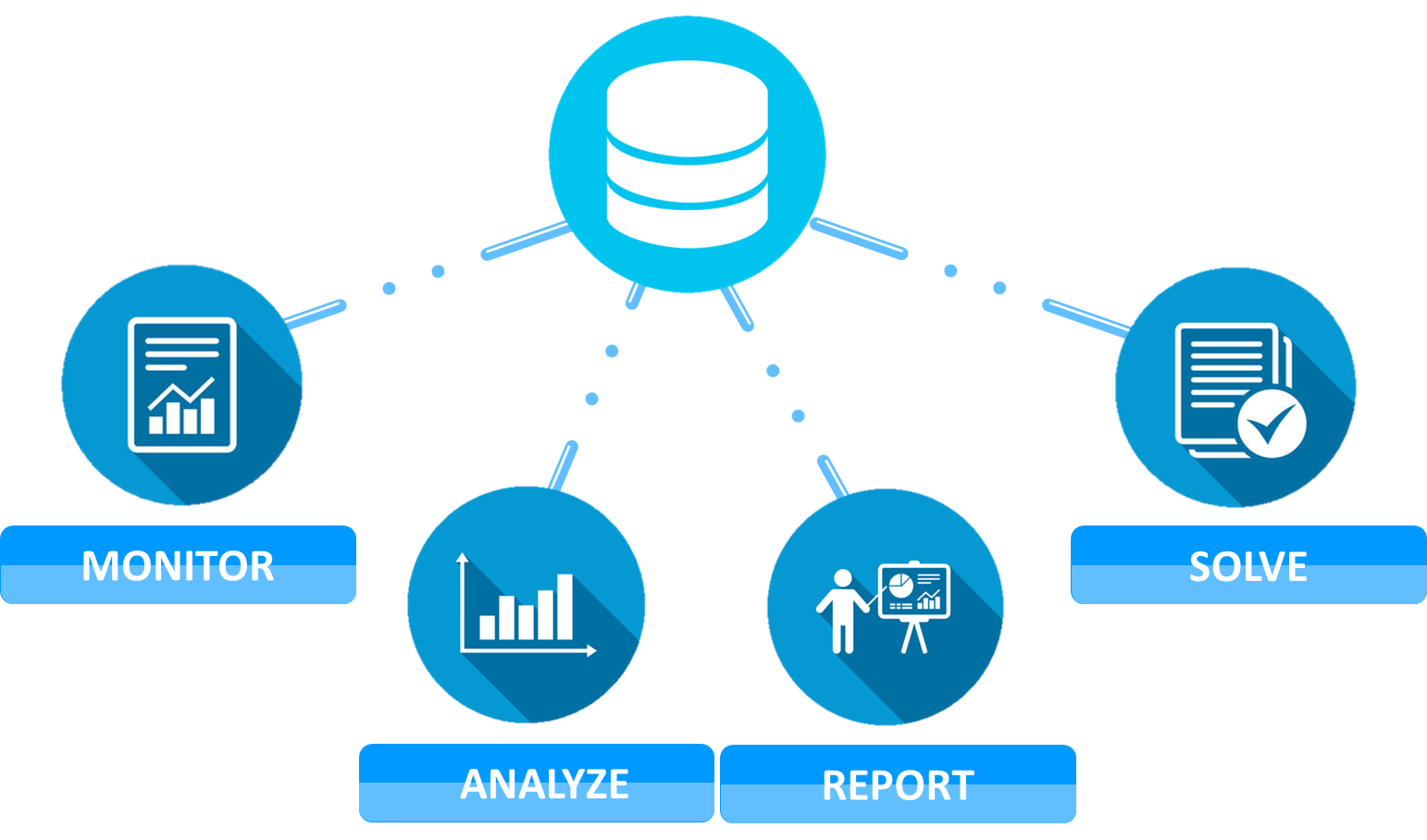

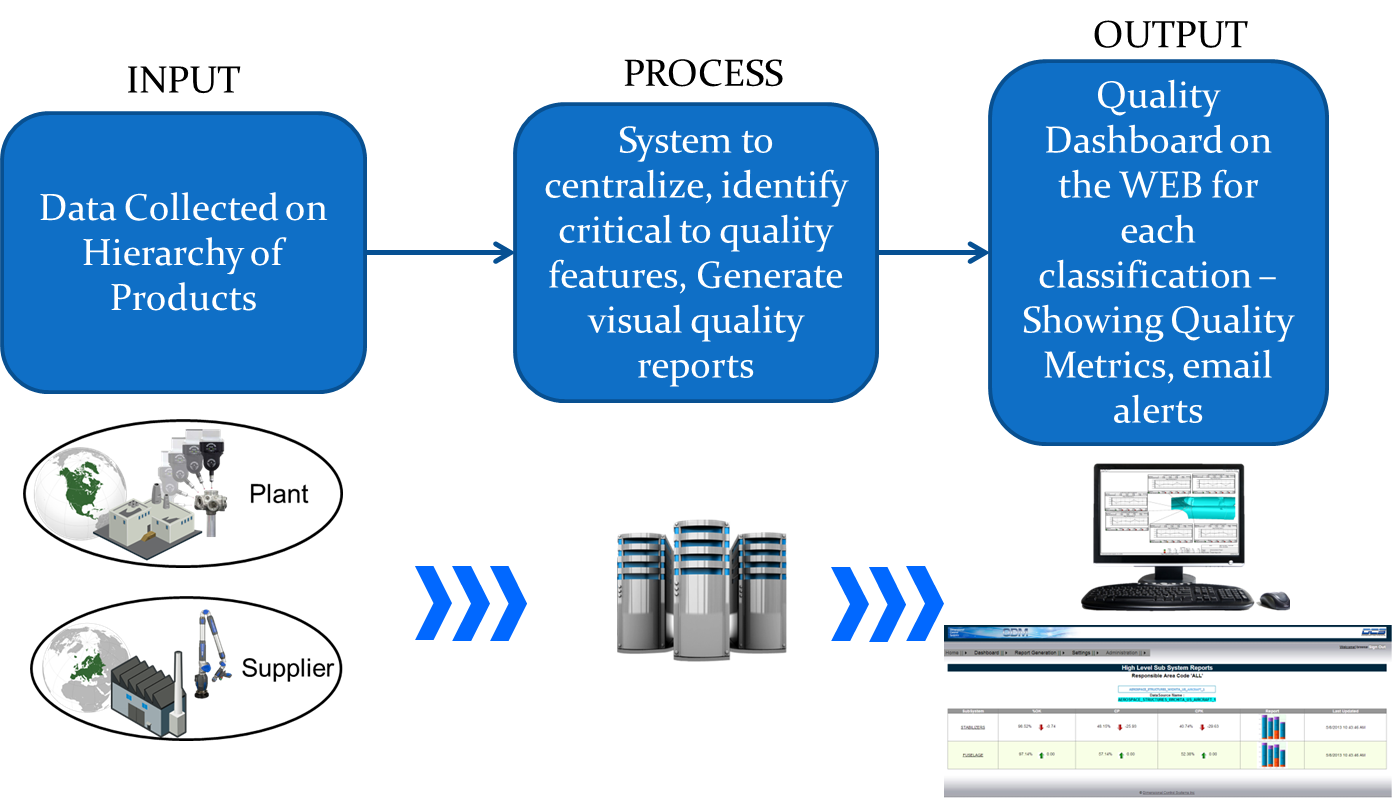

QDM uses a central server to store and unify your data. That data is then available for real-time monitoring, analysis, reporting and problem resolution.

Real-time monitoring of your production line gives you constant visibility into your manufacturing quality. Watch for our of specification parts, or trends towards out-of-spec scenarios.

This reduces downtime, defects and non-conformance by giving you the ability to immediately address issues, as well as solve problems before parts go out-of-spec.

QDM gives you advanced SPC analysis.

This comes in the form of dashboards and analysis reports that can be made available to interested parties across your organization.

These offer analytics in the form of Cpk, Cp, Ppk, Pp as well as comparisons, trends and historical analysis. Choose specific samples based on location, time, machine, part or operator.

QDM offers both custom reporting and automated reporting.

Users can choose specific data sets, then select from pre-made forms to automatically generate customer reports in seconds.

Alternately, users can set up automatic report generation, creating specific reports available when they need them. This can be used to have the previous day's report always available in the morning, or to instantly create historic reports from the previous month, line, production run or other variable.

Use QDM to solve production issues and predict manufacturing problem before they happen.

This gives you the ability to reduce scrap, rework and warranty claims by finding and resolving issues before they become problems.

With trend reports and automated alerts, stay constantly up-to-date on your production quality.

Use custom reports to drill down and find exactly where and why your manufacturing is having issues. Is it a bad part? Is a machine worn out? Is an operator performing poorly? Find the answers you need, fast.

QDM is all about access. It gives you control of access to your data, letting your people access their data fast, and from anywhere, or letting you control it, letting only those with permissions securely access it. This gives you access to the information you need, from any data source, anywhere in the world, on any device.

By choosing off-the-shelf modules and combining them into a system, you have the ability to create a custom system at low cost that can be quickly scaled up or down based on your business demands.

QDM gives you the information you need, when you need it; not just the raw data.

Use your phone, tablet, laptop or workstation PC to view your data from anywhere in the world.

Put the QDM server behind your secure network, or use DCS's secure Cloud Network to control access and keep your data safe.

Once you receive your data, it will be ready to use and share as dashboards, quality metrics, scorecards and interactive graphical and statistical reports.

QDM has three different deployments to make it easy to get up and running. Quickly add modules to any configuration to upgrade in size and scope, or reduce the functionality to just what you need.

Pull all of your data together into one source, and output custom reports for customers and managers.

Use any measurement device and bring all your data into one server to standardize it and make it easy to draw from and report.

Begin with a basic setup and add modules to customize it to fit your business needs.

Create a streamlined quality process across your entire plant. Bring your current processes into the digital world by implementing a QDM system to support.

Monitor and report on production lines. Create dashboards for parts, product lines, projects and individual plants to get instant insight into your quality metrics.

Use manual inputs for hand measurements along with

Utilize advanced SPC analysis to dig into your production data to predict and resolve manufacturing issues.

Track and manage your entire supply chain by connecting them to your system. Automate the collection of their data and standardize it into an easy to use and understand format.

Create dashboards for plants, regions, product line and the entire company to understand your quality at each level of production.

Interconnect your plants to keep track of production quality, allowing advanced analysis of your data to reduce scrap, rework and waste across your entire organization.

Have your own On Site Server Setup or use it as a service in the Cloud

Deploy the server and system behind your firewall, giving you full control of your data and information.

Utilize QDM in the cloud to quickly setup and run, letting DCS handle all of your system's IT requirements, leaving you to focus on what's most important; your quality.

We have one that suits your needs!

DCS will never share your information with a third party or add you to a mailing list without permission. Read our privacy policy to learn more about how DCS protects your information.

DCS Global Headquarters

2805 Bellingham Dr

Troy, Michigan, 48083

Phone: 1.248.269.9777

Fax: 1.248.269.9770

Website: www.3dcs.com

Email: sales@3dcs.com