Expand your tolerance analysis software to include advanced and unique functions

Use Add-on Modules to customize your tolerance analysis software to handle special

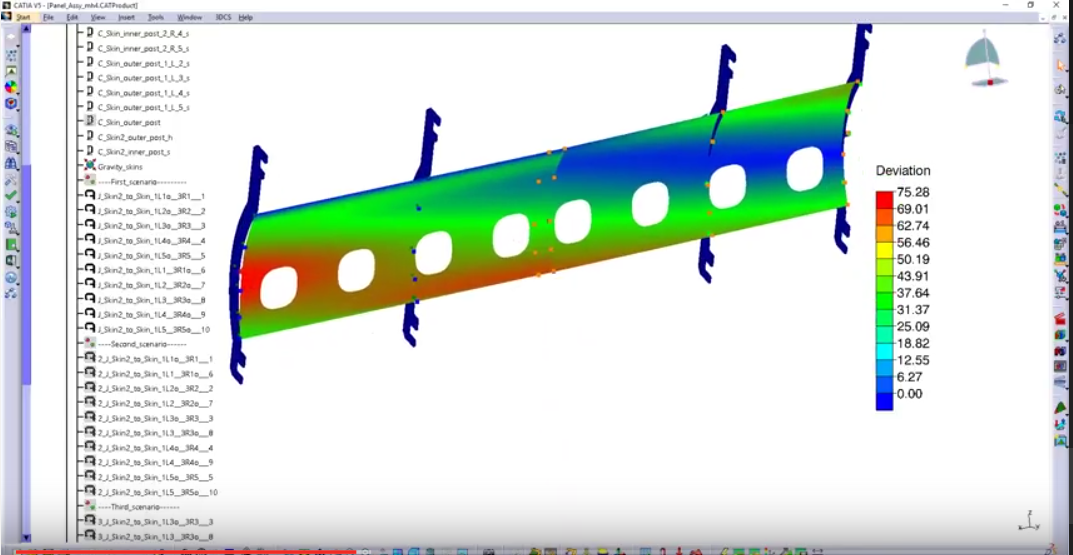

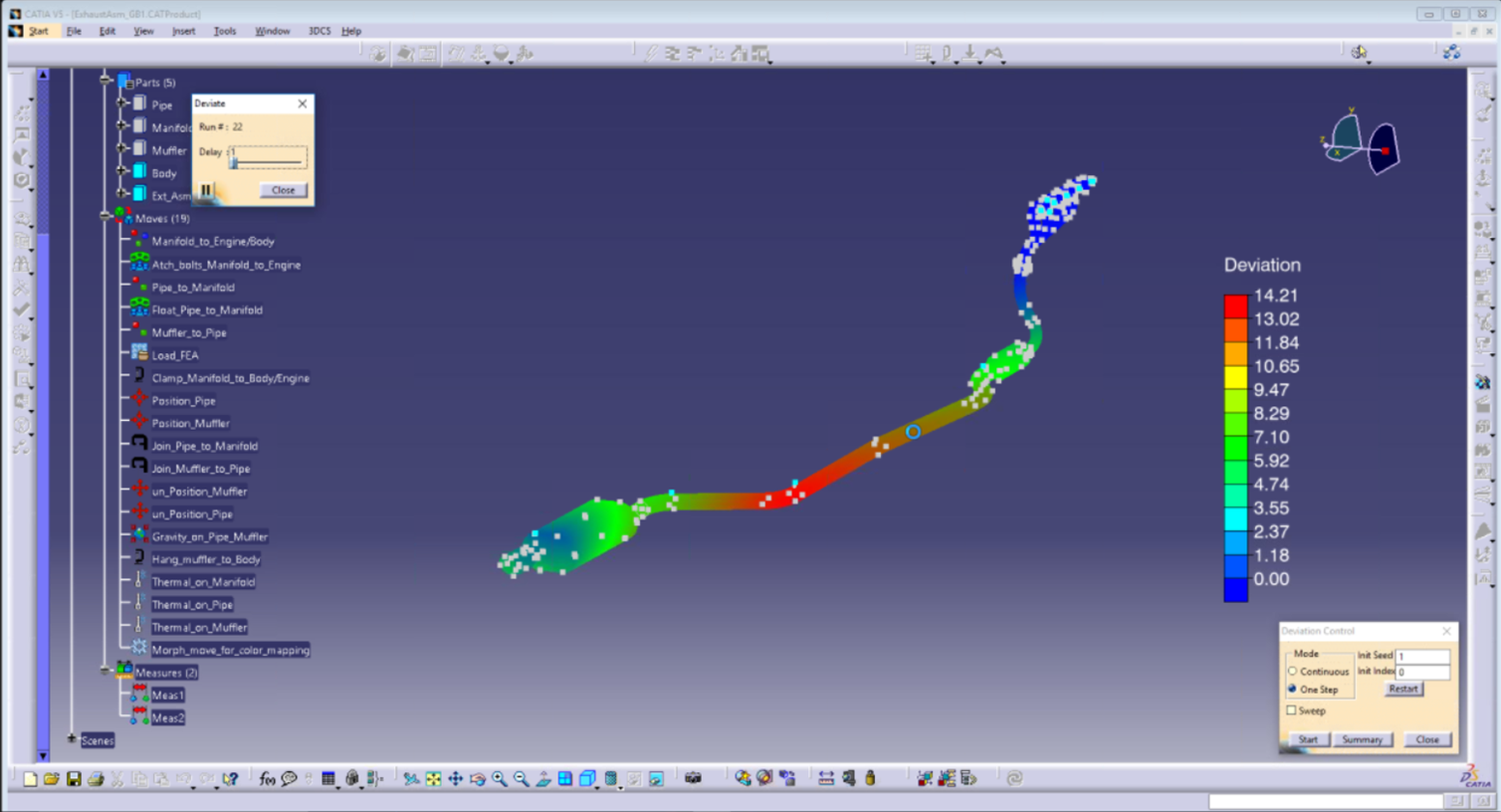

FEA Compliant Modeler - Add Finite Element Analysis for flexible assemblies and forces.

Mechanical Modeler - Add kinematic functions, joints and constraints

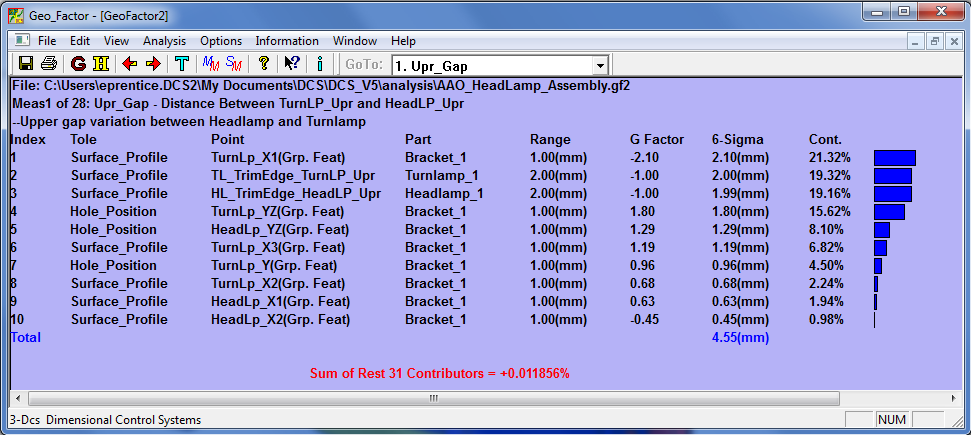

GeoFactor Analyzer - Recommended for use with the base software, GeoFactor analyzes the geometric relationship between parts and tolerances.

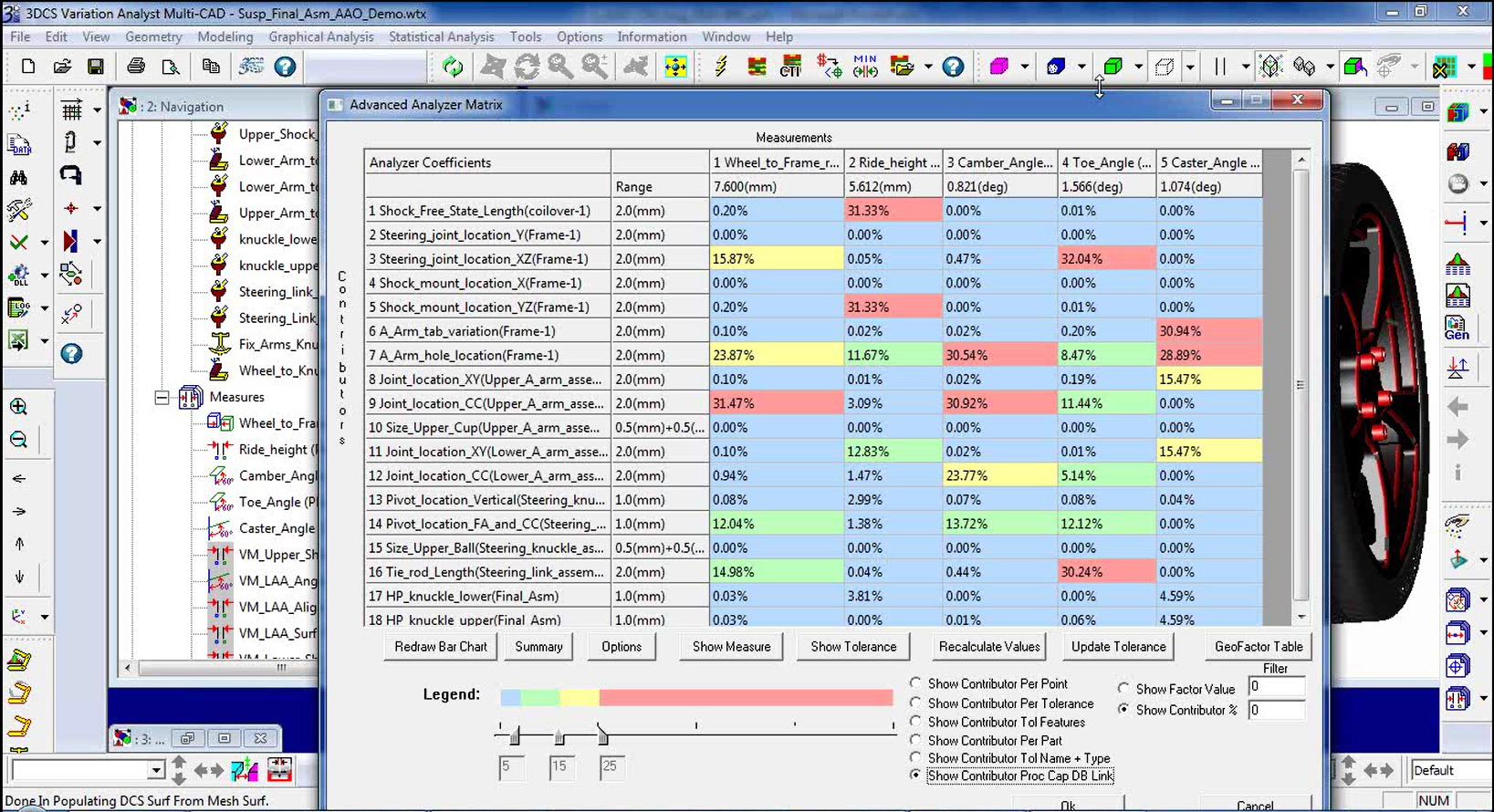

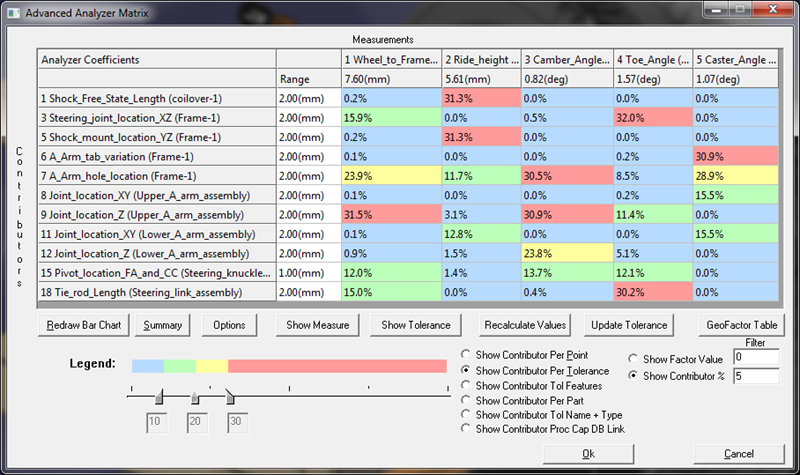

Advanced Analyzer Optimizer - A number of advanced analyzers and optimizers to test datums and locators, view matrices to work with large models and tackle non-linear tolerance stacks.

Visualization Export - Connect your tolerance analysis results with a visualization tool to view your product in realistic life-like rendering incorporating the tolerances and stack-ups.

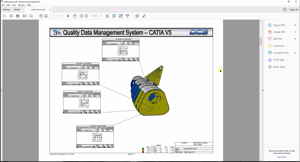

QDM for 3DCS - Leverage your model for downstream quality with measurement plans, CMM routines

Add-on modules make it easy to add advanced options to 3DCS Variation Analyst, customizing it to fit your project requirements and product.

Take your tolerance analysis to the next level with add-on modules offers you advanced analysis to model special cases and complicated assemblies.

Advanced Analysis Functions:

Flexible Parts, Force or Heat?

Flexible Parts, Force or Heat?Use Finite Element Analysis to determine the effect of manufacturing processes on your assembly. Account for welding, clamping, gravity, spring-back and other forces.

Use FEA Mesh to simulate:

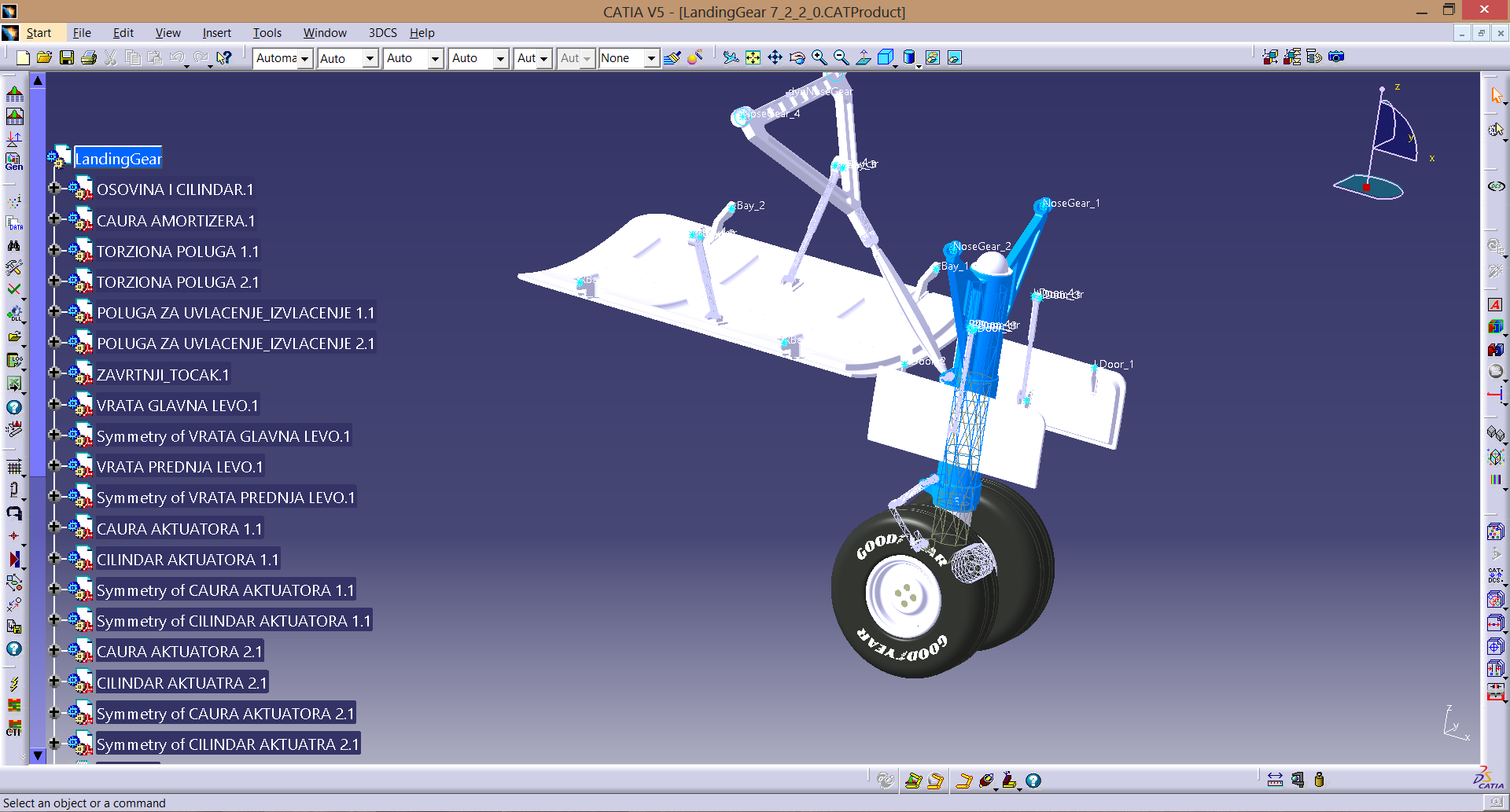

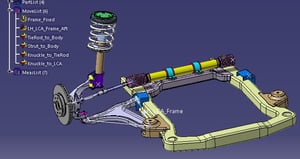

Joints and Constraints, Kinematic Assemblies

Joints and Constraints, Kinematic AssembliesUse kinematic and mechanical joints and constraints in your model. Analyze parts and assemblies through their range of motion.

Benefits:

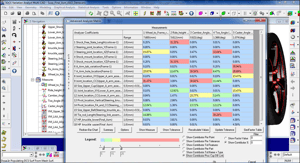

Five Tools in One Module

Five Tools in One Module Analyze your model from a global perspective, viewing all tolerances and measurements in an easy to use and modify matrix. Utilize a series of optimizers to quickly optimize your model for quality, cost or specification.

Five Tools in One Add-on Module:

1. Advanced Analyzer with GeoFactor

2. Critical Tolerance Identifier

3. Tolerance Optimizer

4. Locator Sensitivity Analyzer

5. Simulation-Based Sensitivity

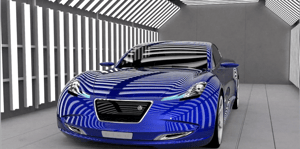

Use your tolerance output with high-end visualization

Use your tolerance output with high-end visualization With the push of a button, connect your 3DCS tolerance analysis model with a high-end visualization tool to generate lifelike images of tolerance scenarios. Determine build objectives and the impact of tolerances on the appearance of your product (Perceived Quality).

View your product with

Create Measurement Plans, CMM Routines and Management Reports from Your CAD Model

Create Measurement Plans, CMM Routines and Management Reports from Your CAD ModelIncorporate your manufacturing process into your tolerance analysis studies by generating measurement plans and inspection plans from the CAD information.

Connect Your CAD with Downstream Quality

Find out how 3DCS add-ons can enhance your analysis.

DCS will never share your information with a third party or add you to a mailing list without permission. Read our privacy policy to learn more about how DCS protects your information.

DCS Global Headquarters

2805 Bellingham Dr

Troy, Michigan, 48083

Phone: 1.248.269.9777

Fax: 1.248.269.9770

Website: www.3dcs.com

Email: sales@3dcs.com